Eccentric Bore Clamp, Block Type

ROEMHELD B1.485 Bore Clamp: Block-type eccentric, for bore diameter 6.6 to 13.8 mm, double acting, max. operating pressure 250 bar

- Double acting

- Operating pressure 250 bar maximum

- Clamping ranges from 6.6 to 13.8 mm

- Maximum pull force 3.8 - 6.3 kN

- Axial clamping force 210 - 720 N

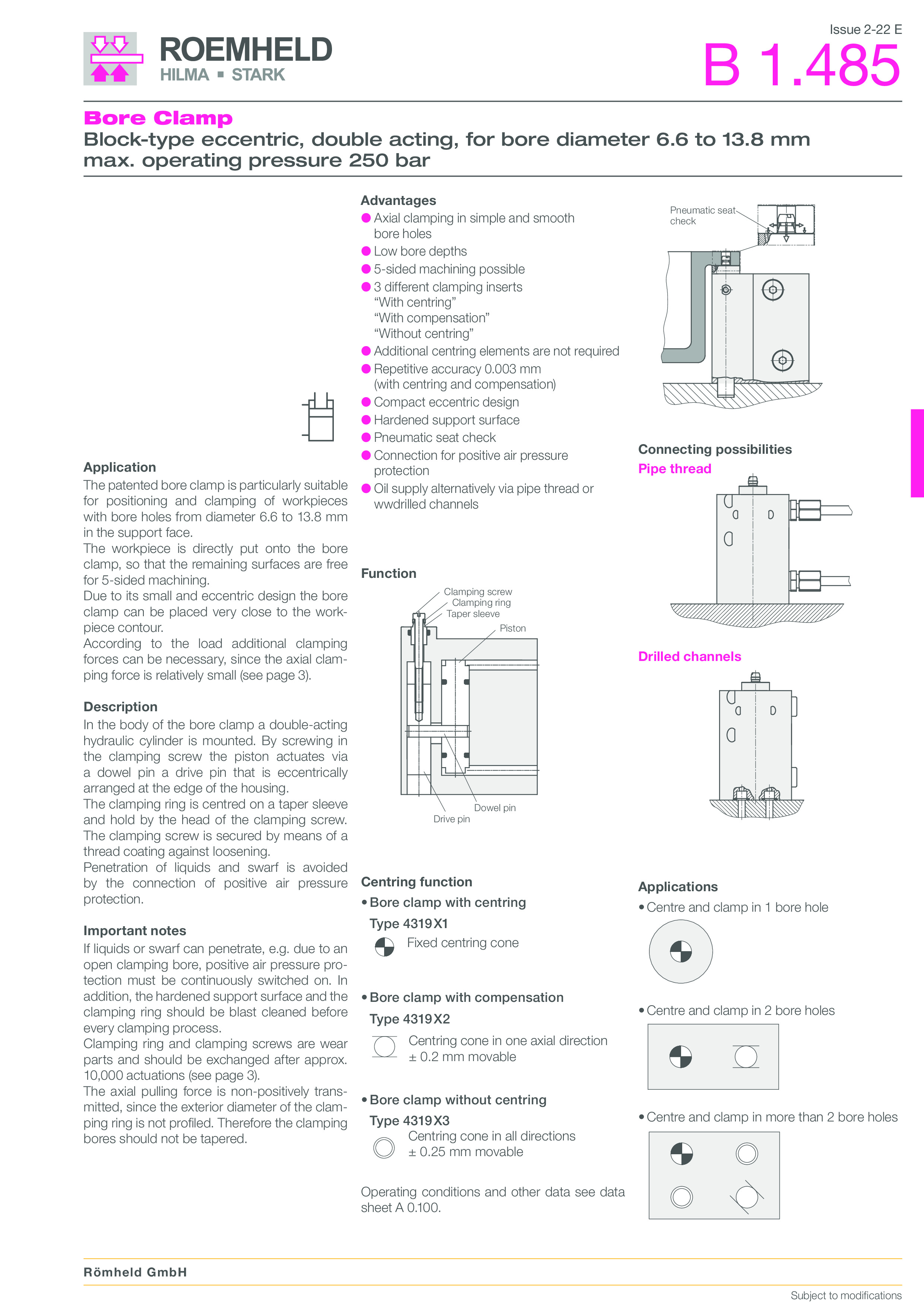

In the body of the bore clamp a double-acting hydraulic cylinder is mounted. By screwing in the clamping screw the piston actuates via a dowel pin a drive pin that is eccentrically arranged at the edge of the housing. The clamping ring is centred on a taper sleeve and hold by the head of the clamping screw. The clamping screw is secured by means of a thread coating against loosening. Penetration of liquids and swarf is avoided by the connection of positive air pressure protection.

Eccentric Bore Clamp, Block Type - ROEMHELD B1.485

- Max. operating pressure 250 bar

- Clamping range: 6.6 - 13.8 mm

- Max. pull force: 3.8 - 6.3 kN

- Axial clamping force: 210 - 720 N

Advantages:

- Axial clamping in simple and smooth bore holes

- Low bore depths

- 5-sided machining possible

- 3 different clamping inserts

“With centring”

“With compensation”

“Without centring” - Additional centring elements are not required

- Compensation of side loads (with centring and compensation)

- Repetitive accuracy 0.003 mm (with centring and compensation)

- Compact eccentric design

- Hardened support surface

- Pneumatic seat check

- Connection for positive air pressure protection

- Oil supply alternatively via pipe thread or drilled channels

Application:

The patented bore clamp is particularly suitable for positioning and clamping of work pieces with bore holes from diameter 6.6 to 13.8 mm in the support face. The workpiece is directly put onto the bore clamp, so that the remaining surfaces are free for 5-sided machining. Due to its small and eccentric design the bore clamp can be placed very close to the workpiece contour. The variants with centring and compensation can compensate side loads. According to the load additional clamping forces can be necessary, since the axial clamping force is relatively small.

Description:

In the body of the bore clamp a double-acting hydraulic cylinder is mounted. By screwing in the clamping screw the piston actuates via a dowel pin a drive pin that is eccentrically arranged at the edge of the housing. The clamping ring is centred on a taper sleeve and hold by the head of the clamping screw. The clamping screw is secured by means of a thread coating against loosening. Penetration of liquids and swarf is avoided by the connection of positive air pressure protection.

ROEMHELD B1.485 Patented, Double-acting Bore Clamp is particularly suitable for positioning and clamping of work pieces with bore holes from diameter 6.6 to 13.8 mm in the support face. The workpiece is directly put onto the bore clamp, so that the remaining surfaces are free for 5-sided machining.

| Quantity | Unit discount | You Save |

|---|