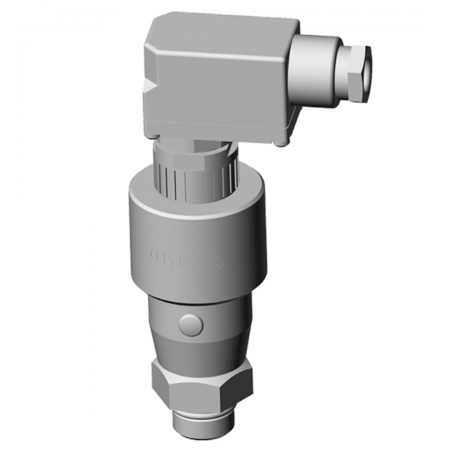

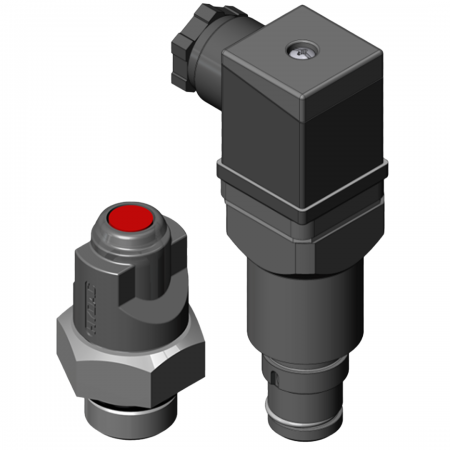

Hydac Clogging Indicators

HYDAC Clogging Indicators provide reliable visual and/or electrical signals when filter elements need replacement due to rising contamination and pressure loss. Available with dynamic or differential pressure detection and a range of response settings, they help ensure system safety and efficient filter use. Easy to install on standard filters, they eliminate guesswork and reduce unnecessary maintenance costs.

Key Features:

- Indicator of dynamic or differential pressure

- Optical, electrical or electronic signal

- Wide different of response pressures