Clamping and Supporting Elements

ROEMHELD B1.730 Clamping and Supporting Element: self-locking, double acting

OBSOLETE ITEM - CONTACT HYQUIP

- Maximum clamping force ranges from 5 to 18 kN

- Maximum operating pressure 300 bar

- Stroke ranges from 5 to 12 mm

- Diameter of the clamping bolt: 12 - 22 mm

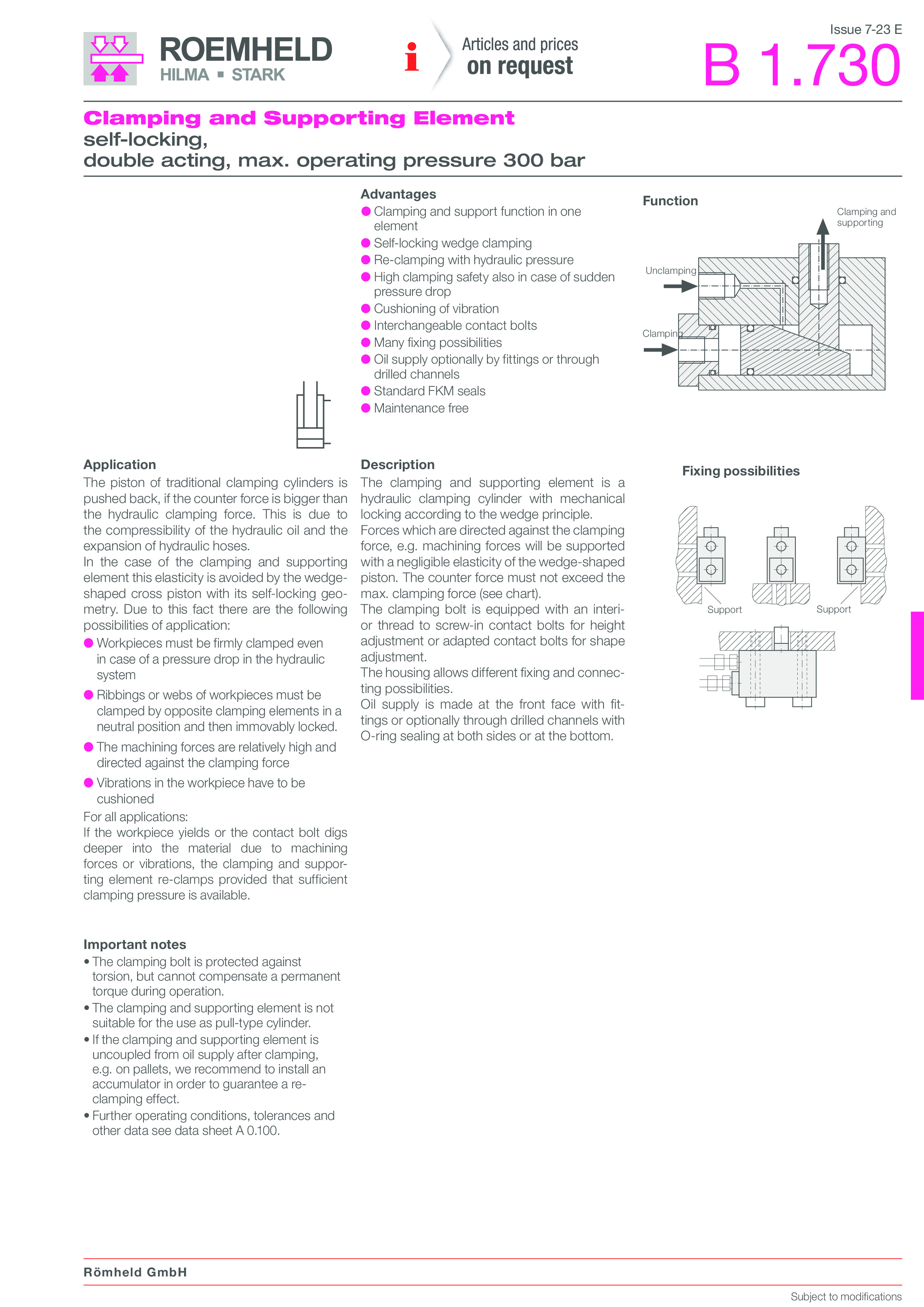

The clamping and supporting element is a hydraulic clamping cylinder with mechanical locking according to the wedge principle. Forces which are directed against the clamping force, e.g. machining forces will be supported with a negligible elasticity of the wedge-shaped piston. The counter force must not exceed the maximum clamping force.

Clamping and Supporting Elements - ROEMHELD B1.730

- Max. clamping force: 5 -18 kN

- Max. operating pressure 300 bar

- Stroke 5 - 12 mm

- Diameter of the clamping bolt: 12 - 22 mm

Advantages:

- Clamping and support function in one element

- Self-locking wedge clamping

- Re-clamping with hydraulic pressure

- High clamping safety also in case of sudden pressure drop

- Cushioning of vibration

- Interchangeable contact bolts

- Many fixing possibilities

- Oil supply optionally by fittings or through drilled channels

- Standard FKM seals

- Maintenance free

Description:

The clamping and supporting element is a hydraulic clamping cylinder with mechanical locking according to the wedge principle. Forces which are directed against the clamping force, e.g. machining forces will be supported with a negligible elasticity of the wedge-shaped piston. The counter force must not exceed the max. clamping force. The clamping bolt is equipped with an interior thread to screw-in contact bolts for height adjustment or adapted contact bolts for shape adjustment. The housing allows different fixing and connecting possibilities. Oil supply is made at the front face with fittings or optionally through drilled channels with O-ring sealing at both sides or at the bottom.

Application:

The piston of traditional clamping cylinders is pushed back, if the counter force is bigger than the hydraulic clamping force. This is due to the compressibility of the hydraulic oil and the expansion of hydraulic hoses. In the case of the clamping and supporting element this elasticity is avoided by the wedgeshaped cross piston with its self locking geometry. Due to this fact there are the following possibilities of application:

- Workpieces must be firmly clamped even in case of a pressure drop in the hydraulic system

- Ribbings or webs of workpieces must be clamped by opposite clamping elements in a neutral position and then immovably locked.

- The machining forces are relatively high and directed against the clamping force

- Vibrations in the workpiece have to be cushioned

For all applications:

If the workpiece yields or the contact bolt digs deeper into the material due to machining forces or vibrations, the clamping and supporting element re-clamps provided that sufficient clamping pressure is available.

| Quantity | Unit discount | You Save |

|---|