Double-acting Block Clamps

ROEMHELD B1.8233 Block Clamps: Versions with / without self-locking double acting

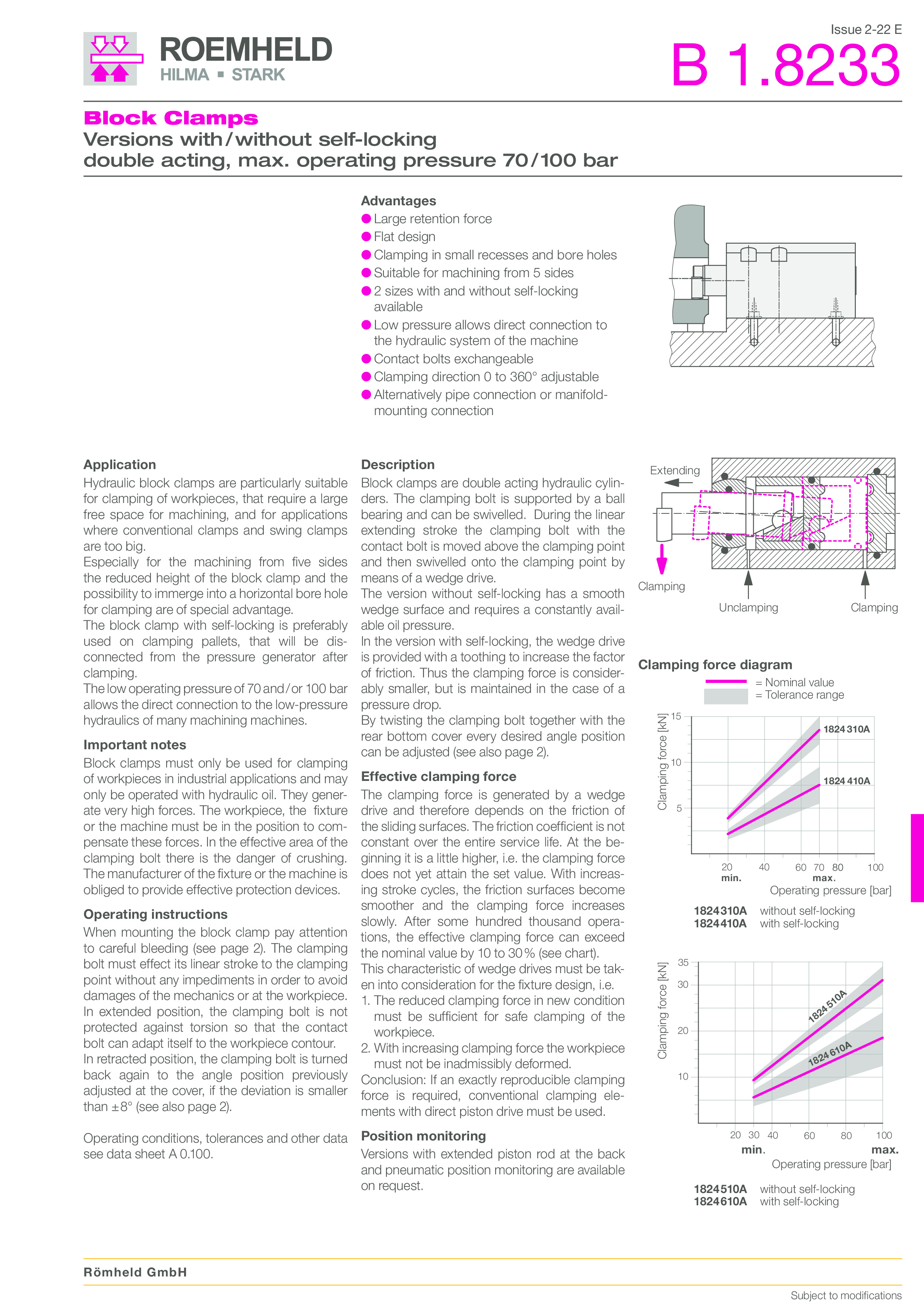

- Maximum clamping force ranges from 7.5 to 18.5 kN

- Maximum operating pressure 70 / 100 bar

- Clamping stroke: 6 - 8 mm

- 2 sizes available

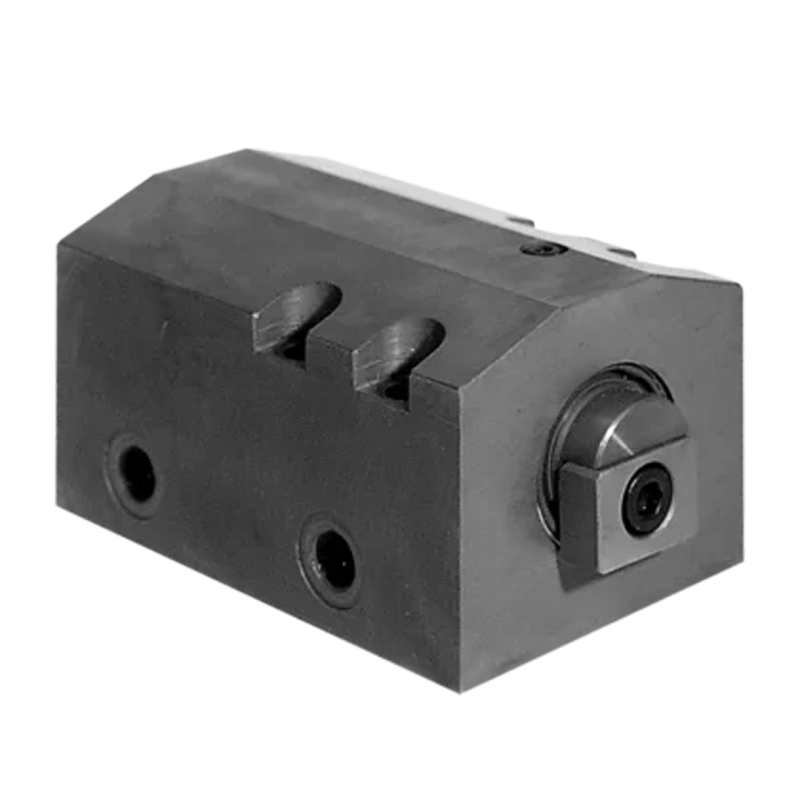

Block clamps are double acting hydraulic cylinders. The clamping bolt is supported by a ball bearing and can be swivelled. During the linear extending stroke the clamping bolt with the contact bolt is moved above the clamping point and then swivelled onto the clamping point by means of a wedge drive. The version without self-locking has a smooth wedge surface and requires a constantly available oil pressure

Double-acting Block Clamps - ROEMHELD B1.8233

- Max. clamping force: 7.5 - 18.5 kN

- Max. operating pressure 70 / 100 bar

- Clamping stroke: 6 - 8 mm

- 2 sizes available

Advantages:

- Large retention force

- Flat design

- Clamping in small recesses and bore holes

- Suitable for machining from 5 sides

- 2 sizes with and without self-locking available

- Low pressure allows direct connection to the hydraulic system of the machine

- Contact bolts exchangeable

- Clamping direction 0 to 360° adjustable

- Alternatively pipe connection or manifoldmounting connection

Description:

Block clamps are double acting hydraulic cylinders. The clamping bolt is supported by a ball bearing and can be swivelled. During the linear extending stroke the clamping bolt with the contact bolt is moved above the clamping point and then swivelled onto the clamping point by means of a wedge drive. The version without self-locking has a smooth wedge surface and requires a constantly available oil pressure. In the version with self-locking, the wedge drive is provided with a toothing to increase the factor of friction. Thus the clamping force is considerably smaller, but is maintained in the case of a pressure drop. By twisting the clamping bolt together with the rear bottom cover every desired angle position can be adjusted

Application:

Hydraulic block clamps are particularly suitable for clamping of workpieces, that require a large free space for machining, and for applications where conventional clamps and swing clamps are too big. Especially for the machining from five sides the reduced height of the block clamp and the possibility to immerge into a horizontal bore hole for clamping are of special advantage. The block clamp with self-locking is preferably used on clamping pallets, that will be disconnected from the pressure generator after clamping. The low operating pressure of 70 and/or 100 bar allows the direct connection to the low-pressure hydraulics of many machining machines.

| Quantity | Unit discount | You Save |

|---|