Mini Compact Clamps Cartridge Type

ROEMHELD B1.8271 Mini Compact Clamp: Cartridge type, clamping force 1.3 kN double acting, max. operating pressure 200 bar

- Clamping force 1.3 kN

- Maximum operating pressure 200 bar

- Clamping force at 200 bar: 1.3 kN

- Usable clamping stroke: 5 mm

- Adm. flow rate 5 cm³/s

- Minimum pressure 20 bar

The hydraulic mini compact clamp is a double acting pull-type cylinder where a part of the linear stroke is used to swing the clamping lever onto the workpiece. In order to minimise the dimensions, the usual flange for screw fixing is omitted.

Mini Compact Clamps Cartridge Type - ROEMHELD B1.8271

- Clamping force 1.3 kN

- Max. operating pressure 200 bar

- Clamping force at 200 bar: 1.3 kN

- Usable clamping stroke: 5 mm

- Adm. flow rate 5 cm³/s

- Minimum pressure 20 bar

Advantages:

- Minimum dimensions (Ø 22 mm)

- Partially immersed body

- Space-saving integration by a patented fixing principle

- Housing can be rotated by 360°

- Mounting without pipes

- Workpiece clamping without any side loads

- Narrow clamping lever

- Metallic wiper edge

- Mounting position: any

Description:

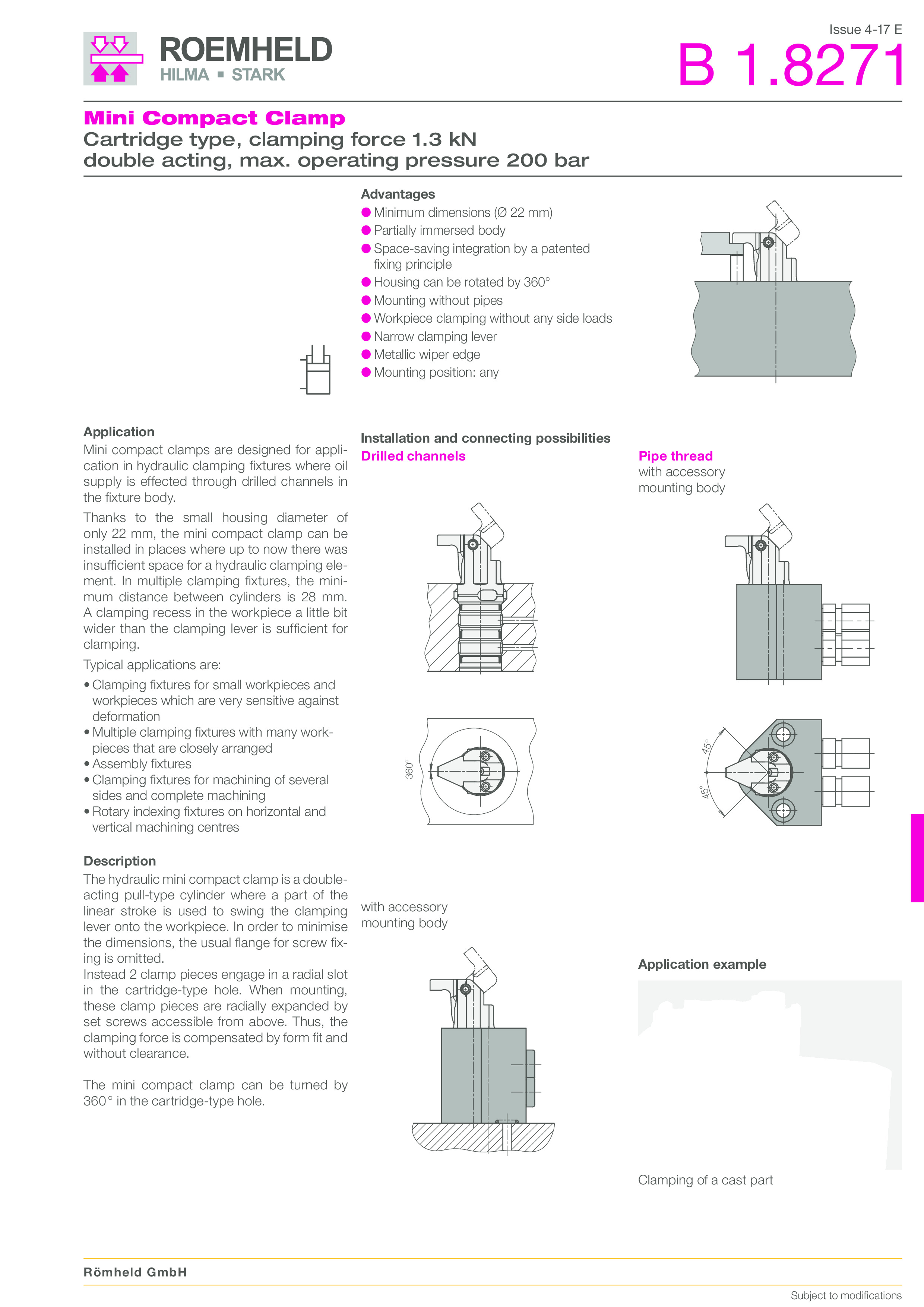

The hydraulic mini compact clamp is a doubleacting pull-type cylinder where a part of the linear stroke is used to swing the clamping lever onto the workpiece. In order to minimise the dimensions, the usual flange for screw fixing is omitted. Instead 2 clamp pieces engage in a radial slot in the cartridge-type hole. When mounting, these clamp pieces are radially expanded by set screws accessible from above. Thus, the clamping force is compensated by form fit and without clearance.

Application:

Mini compact clamps are designed for application in hydraulic clamping fixtures where oil supply is effected through drilled channels in the fixture body. Thanks to the small housing diameter of only 22 mm, the mini compact clamp can be installed in places where up to now there was insufficient space for a hydraulic clamping element. In multiple clamping fixtures, the minimum distance between cylinders is 28 mm. A clamping recess in the workpiece a little bit wider than the clamping lever is sufficient for clamping. Typical applications are:

- Clamping fixtures for small workpieces and workpieces which are very sensitive against deformation

- Multiple clamping fixtures with many workpieces that are closely arranged

- Assembly fixtures

- Clamping fixtures for machining of several sides and complete machining

- Rotary indexing fixtures on horizontal and vertical machining centres

| Quantity | Unit discount | You Save |

|---|