Double-acting Intensifiers with Pre-loaded Valve

ROEMHELD D8.751 Compact Intensifieirs that convert the hydraulic pressure input into a higher pressure output.

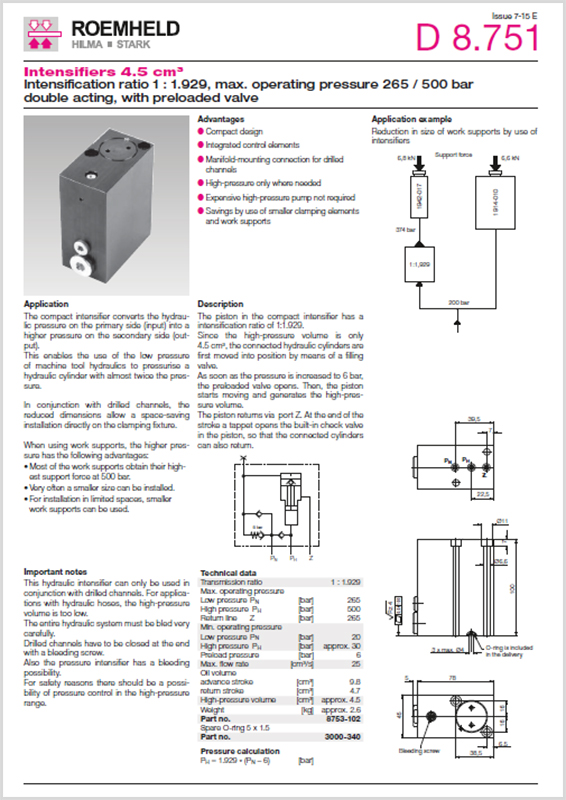

- Intensification ratio 1:1.929

- Max. operating pressure 265/500 bar

- Double acting

- with preloaded valve

- Intensification ratio: 1:1.929

- Intensification volume: 4,5 cm³

- Max. flow rate: 25 cm³/s (low-pressure side)

- Max. operating pressure: 265 bar (low-pressure side)

Double-acting Intensifiers with Pre-loaded Valve - ROEMHELD D8.751

- Intensification ratio 1:1.929

- Max. operating pressure 265/500 bar

- Double acting

- with preloaded valve

- Intensification ratio: 1:1.929

- Intensification volume: 4,5 cm³

- Max. flow rate: 25 cm³/s (low-pressure side)

- Max. operating pressure: 265 bar (low-pressure side)

Advantages:

- Compact design

- Integrated control elements

- Manifold-mounting connection for drilled channels

- High-pressure only where needed

- Expensive high-pressure pump not required

- Savings by use of smaller clamping elements and work supports

Application:

The compact intensifier converts the hydraulic pressure on the primary side (input) into a higher pressure on the secondary side (output). This enables the use of the low pressure of machine tool hydraulics to pressurise a hydraulic cylinder with almost twice the pressure. In conjunction with drilled channels, the reduced dimensions allow a space-saving installation directly on the clamping fixture. When using work supports, the higher pressure has the following advantages:

- Most of the work supports obtain their highest support force at 500 bar

- Very often a smaller size can be installed

- For installation in limited spaces, smaller work supports can be used

Description:

The piston in the compact intensifier has a intensification ratio of 1:1.929. Since the high-pressure volume is only 4.5 cm3, the connected hydraulic cylinders are first moved into position by means of a filling valve. As soon as the pressure is increased to 6 bar, the preloaded valve opens. Then, the piston starts moving and generates the high-pressure volume. The piston returns via port Z. At the end of the stroke a tappet opens the built-in check valve in the piston, so that the connected cylinders can also return.

If you can’t find what you are looking for, need product pricing, delivery, technical support or associated services CONTACT HYQUIP or call our sales office +44 (0)1204 699959

| Quantity | Unit discount | You Save |

|---|