Hydro Cylinders with Locking Piston

ROEMHELD B1.711 Hydro Cylinder with Locking Piston single acting with spring return

- 3 body variants; threaded-body, block and low-block cylinders

- Single acting with spring return

- Maximum operating pressure 500 bar

- Fixtures without tubes are possible

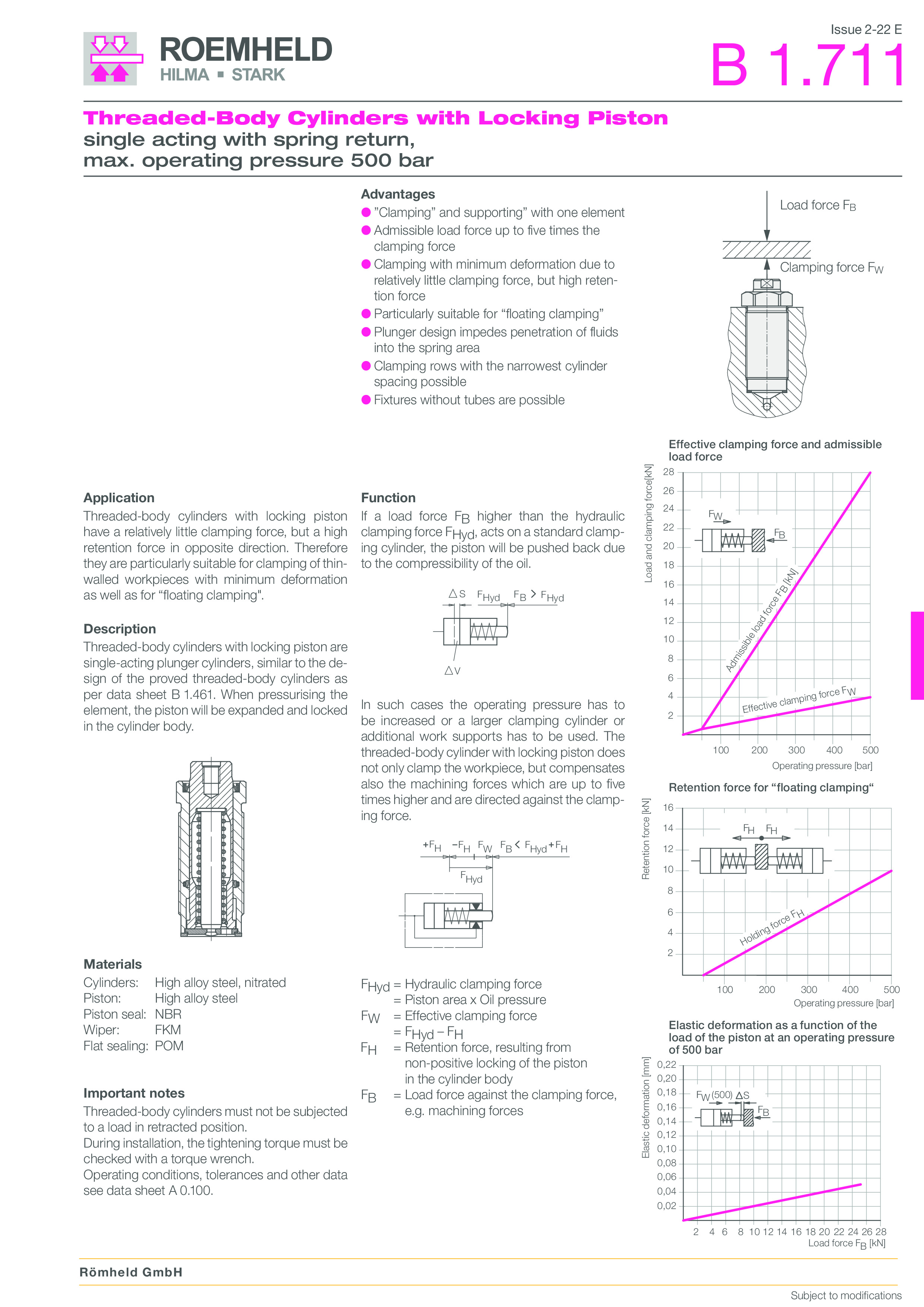

Hydro cylinders with locking piston are singleacting plunger cylinders, similar to the design of the proved threaded-body cylinders as per data sheet B 1.461. When pressurising the element, the piston will be expanded and locked in the cylinder body.

Hydro Cylinders with Locking Piston - ROEMHELD B1.711

- 3 body variants; threaded-body, block and low-block cylinders

- Single acting with spring return

- Max. operating pressure 500 bar

- Fixtures without tubes are possible

Description:

Hydro cylinders with locking piston are singleacting plunger cylinders, similar to the design of the proved threaded-body cylinders as per data sheet B 1.461. When pressurising the element, the piston will be expanded and locked in the cylinder body.

Advantages:

- “Clamping” and “Supporting” with one element

- Admissible support force up to five times the clamping force

- Clamping with minimum deformation due to relatively little clamping force, but high retention force

- Particularly suitable for “floating clamping”

- 3 variants of bodies

- Plunger design impedes penetration of fluids into the spring area.

- Spacings between cylinders can be minimised when cylinders are arranged in a row

- Fixtures without tubes are possible

Threaded-body cylinder with locking piston

- Part number: 1462-847

- Part number additional seal: 3000-842

Application example:

Simple collet for “floating clamping” Two clamping bars with threaded-body cylinders with locking piston are fixed on a base plate and hydraulically connected by drilled channels. The axial block fixed in the centre is used as guide for both clamping jaws. An installed return spring moves the clamping jaws to its off-position. “Floating” clamping, i.e. the uniform and tongs-type contact at the workpiece independent of its position is possible due to the hydraulic pressure compensation between the cylinders. Only different spring forces can influence the uniformity. After the pressure increase, the two locking pistons avoid a “further floating” of the clamping point.

Block cylinder with locking piston

- Part number: 1512-801

Application example:

“Floating clamping” The workpiece is pre-clamped against the stop and thereby positioned by a standard block cylinder. Then, controlled by a sequence valve, the two block-cylinders with locking piston are pressurised. The effective clamping force FW is uniformly generated by hydraulic pressure at both sides. A “further floating” of the web due to machining forces is avoided due to locking of both pistons. The maximum retention force FH can be taken from the diagram. This arrangement is particularly suitable to absorb vibrations at ribs and webs.

Low-block clamping cylinder with locking piston

- Part number: 1372-800

Accessories/Spare parts

- Plug G 1/4: 3610-264

- Clamping lever, spare part: 3542-081

- Leg spring, spare part: 3715-104

Application example:

Clamping and supporting with minimum deformation The workpieces are clamped with minimum deformation and relatively little piston force. Since the admissible support force FB is up to five times higher than the effective clamping force, the clamping forces which act against the right-hand low-block clamping cylinder with locking piston are securely compensated. With this arrangement the available machining area at the fixture is optimally used.

| Quantity | Unit discount | You Save |

|---|