Swing Clamps with Sturdy Swing Mechanism Bottom Flange

ROEMHELD B1.854 Swing Clamps with Sturdy Swing Mechanism: Bottom flange type, with optional position monitoring, double acting

- Maximum operating pressure 350 bar

- Maximum clamping force: 6 - 22 kN

- Rod diameter: 16 - 32 mm

- Piston diameter: 23 - 45 mm

- Maximum flow rate: 10 - 57 cm³/s

This hydraulic swing clamp is a pull-type cylinder where a part of the total stroke is used to swing the piston. The favourable area ratio (piston/piston rod) allows high clamping forces already at relatively low oil pressures. Due to the sturdy swing mechanism the angle position of the clamping arm remains the same after a slight collision with the workpiece during loading or unloading.

Swing Clamps with Sturdy Swing Mechanism Bottom Flange Type - ROEMHELD B1.854

- Max. operating pressure 350 bar

- Max. clamping force: 6 - 22 kN

- Rod diameter: 16 - 32 mm

- Piston diameter: 23 - 45 mm

- Clamping stroke: 12/15 mm

- Max. flow rate: 10 - 57 cm³/s

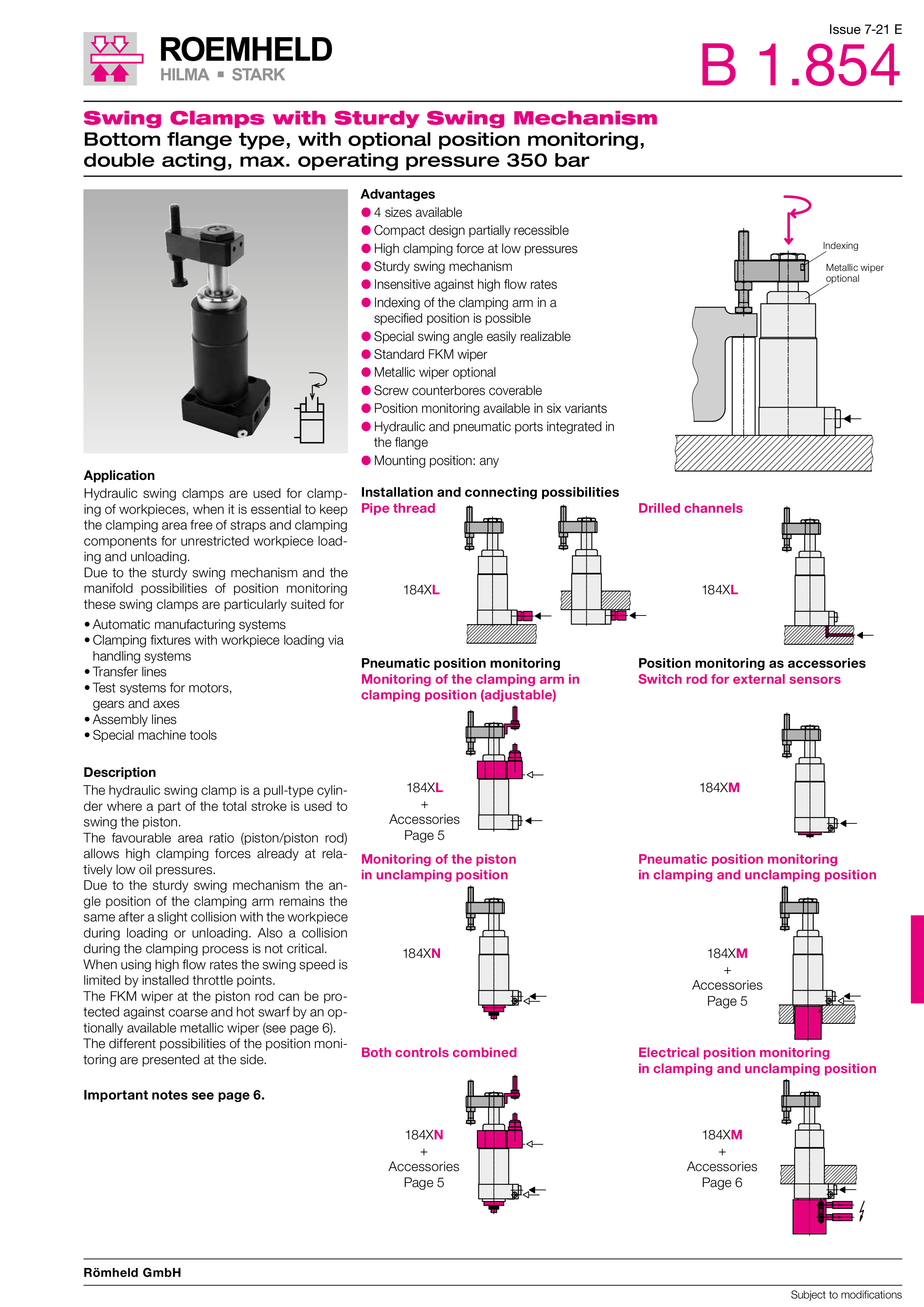

Advantages:

- 4 sizes available

- Compact design partially recessible

- High clamping force at low pressures

- Sturdy swing mechanism

- Insensitive against high flow rates

- Indexing of the clamping arm in a specified position is possible

- Special swing angle easily realizable

- Standard FKM wiper

- Metallic wiper optional

- Screw counterbores coverable

- Position monitoring available in six variants

- Hydraulic and pneumatic ports integrated in the flange

- Mounting position: any

Application:

Hydraulic swing clamps are used for clamping of workpieces, when it is essential to keep the clamping area free of straps and clamping components for unrestricted workpiece loading and unloading. Due to the sturdy swing mechanism and the manifold possibilities of position monitoring these swing clamps are particularly suited for:

- Automatic manufacturing systems

- Clamping fixtures with workpiece loading via handling systems

- Transfer lines

- Test systems for motors, gears and axes

- Assembly lines

- Special machine tools

Description:

The hydraulic swing clamp is a pull-type cylinder where a part of the total stroke is used to swing the piston. The favourable area ratio (piston/piston rod) allows high clamping forces already at relatively low oil pressures. Due to the sturdy swing mechanism the angle position of the clamping arm remains the same after a slight collision with the workpiece during loading or unloading. Also a collision during the clamping process is not critical. When using high flow rates the swing speed is limited by installed throttle points. The FKM wiper at the piston rod can be protected against coarse and hot swarf by an optionally available metallic wiper. The different possibilities of the position monitoring are presented at the side.

| Quantity | Unit discount | You Save |

|---|