Hydraulically Extending Work Supports with Spring Force Contact

ROEMHELD B1.914 Work Supports: Extending hydraulically – contact by spring force, double acting

OBSOLETE ITEM - CONTACT HYQUIP

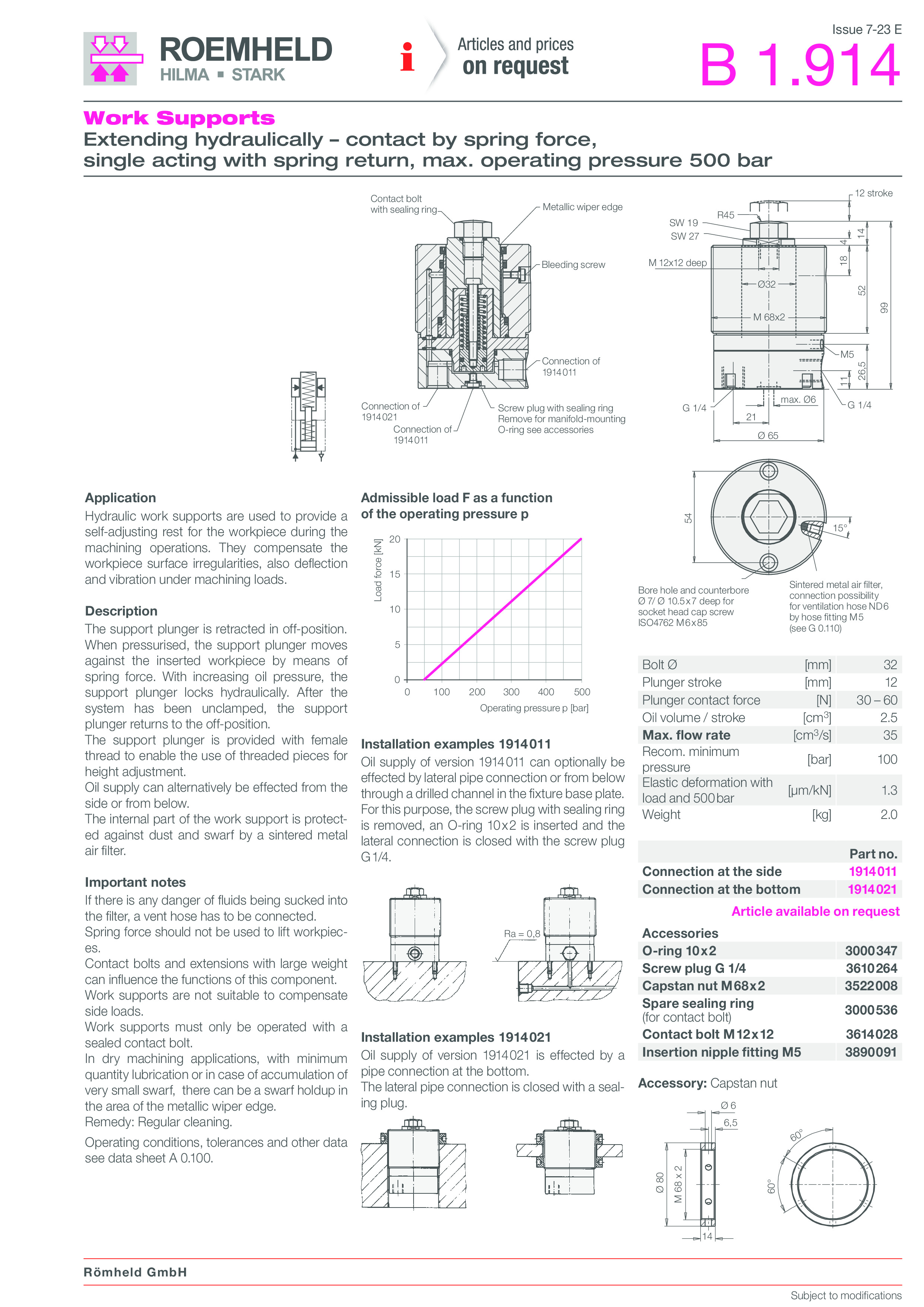

- Maximum operating pressure 500 bar

- External thread: M68

- Maximum load force: 20 kN

- Plunger diameter: 32 mm

- Plunger stroke: 12 mm

- Maximum flow rate: 35 cm³/s

- Elastic deformation: 1.3 µm/kN

Work supports are used to provide a self-adjusting rest to avoid deflection and vibration of the workpieces during machining. It is recommended to use double-acting elements if applied in larger hydraulic clamping fixtures with long lines, especially if the return oil is cycled and has to return in a predetermined time.

| Part Number | Material Number | Type | Plunger Diameter | Plunger Stroke | Price | Add to Parts List |

|---|---|---|---|---|---|---|

| 1914-010 | with Port at the side | 32mm | 12mm | On Enquiry | ||

| 1914-020 | with Port at the bottom | 32mm | 12mm | On Enquiry | ||

| 3000-347 | O-ring 10 x 2 | 32mm | 12mm | £3.61 £4.33 Inc. VAT |

|

|

| 3610-006 | Screw plug G 1/4 | 32mm | 12mm | On Enquiry | ||

| 3522-008 | Capstan nut M 68 x 2 | 32mm | 12mm | On Enquiry | ||

| 3000-536 | Spare O-ring | 32mm | 12mm | On Enquiry | ||

| 3614-028 | Contact bolt M 12 x 12 | 32mm | 12mm | £11.58 £13.90 Inc. VAT |

|

Hydraulically Extending Work Supports with Spring Force Contact - ROEMHELD B1.914

- Max. operating pressure 500 bar

- External thread: M68

- Max. load force: 20 kN

- Plunger diameter: 32 mm

- Plunger stroke: 12 mm

- Max. flow rate: 35 cm³/s

- Elastic deformation: 1.3 µm/kN

Application:

Work supports are used to provide a self-adjusting rest to avoid deflection and vibration of the workpieces during machining. It is recommended to use double-acting elements if applied in larger hydraulic clamping fixtures with long lines, especially if the return oil is cycled and has to return in a predetermined time.

Description:

This hydraulic work support contains a double acting sliding cylinder. If pressurised at port “A” the piston pushes the plunger with little force against the workpiece by means of a spring. As soon as the piston has touched the internal stop, the pressure rises and thus the locking of the plunger. The plunger retracts into de-pressurised mode automatically after the pressure supply has been transferred to port “E”. If the admissible flow rate is surpassed, the plunger will lock before it has touched the workpiece. With type 1911-006 it is possible to effect locking separately through port "K". The internal part of the work support is protected against dust and swarf by a sintered metal air filter.

| Quantity | Unit discount | You Save |

|---|