Work Supports with Spring Force Contact or Air Pressure

ROEMHELD B1.921 Work Supports: contact by spring force or air pressure, single acting

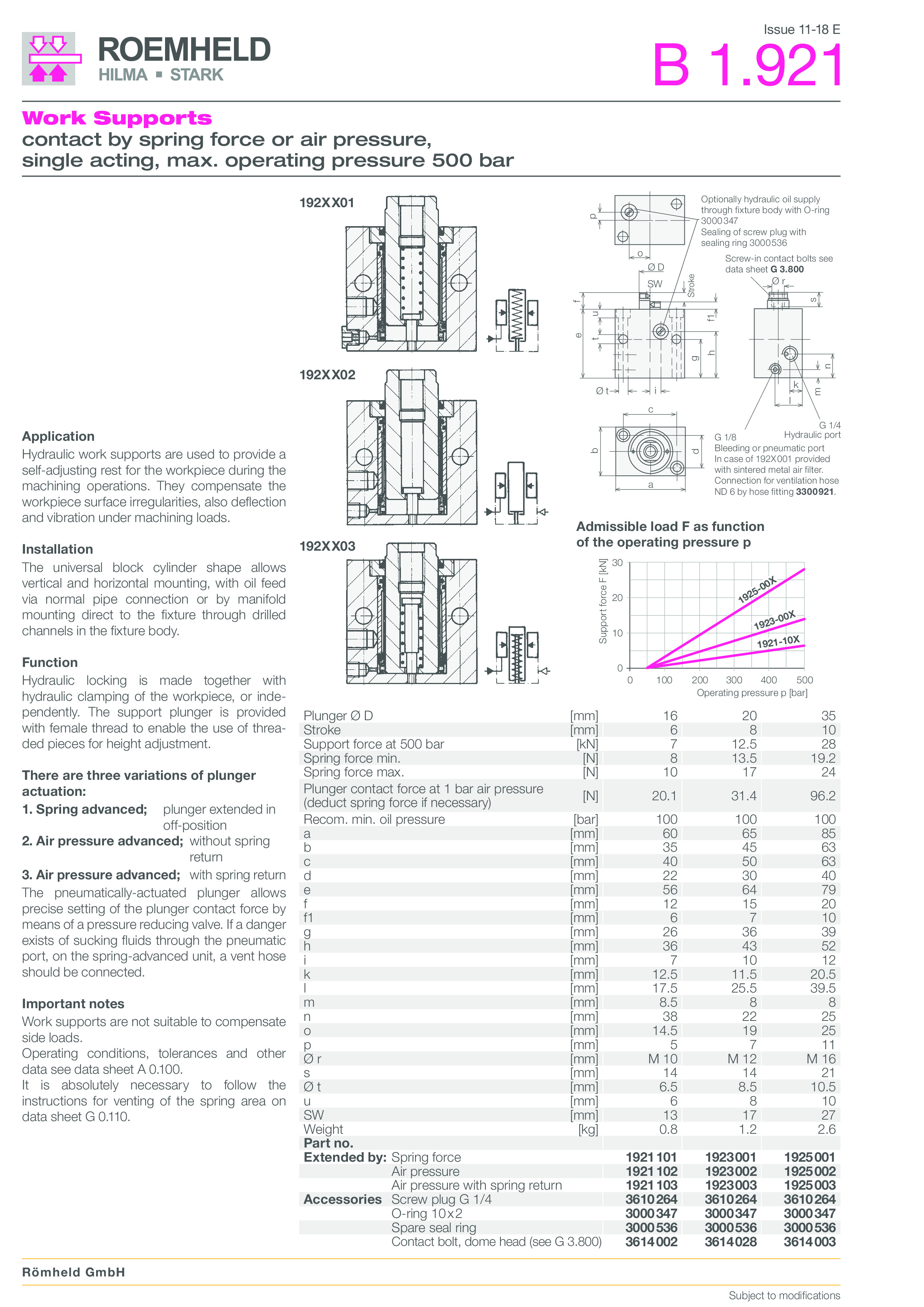

- Maximum operating pressure 500 bar

- Cross section of the body: 60x35 - 85x63 mm

- Maximum load force: 7 - 28 kN

- Plunger diameter: 16 - 35 mm

- Plunger stroke: 6 - 10 mm

- Maximum flow rate: -

- Elastic deformation: 1.3 - 3.6 µm/kN

Hydraulic work supports are used to provide a self-adjusting rest for the workpiece during the machining operations. They compensate the workpiece surface irregularities, also deflection and vibration under machining loads.

Work Supports with Spring Force Contact or Air Pressure - ROEMHELD B1.921

- Max. operating pressure 500 bar

- Cross section of the body: 60x35 - 85x63 mm

- Max. load force: 7 - 28 kN

- Plunger diameter: 16 - 35 mm

- Plunger stroke: 6 - 10 mm

- Max. flow rate: -

- Elastic deformation: 1.3 - 3.6 µm/kN

Application:

Hydraulic work supports are used to provide a self-adjusting rest for the workpiece during the machining operations. They compensate the workpiece surface irregularities, also deflection and vibration under machining loads.

Installation:

The universal block cylinder shape allows vertical and horizontal mounting, with oil feed via normal pipe connection or by manifold mounting direct to the fixture through drilled channels in the fixture body.

Function:

Hydraulic locking is made together with hydraulic clamping of the workpiece, or independently. The support plunger is provided with female thread to enable the use of threaded pieces for height adjustment. There are three variations of plunger actuation:

- Spring advanced; plunger extended in off-position

- Air pressure advanced; without spring return

- Air pressure advanced; with spring return

The pneumatically-actuated plunger allows precise setting of the plunger contact force by means of a pressure reducing valve. If a danger exists of sucking fluids through the pneumatic port, on the spring-advanced unit, a vent hose should be connected.

| Quantity | Unit discount | You Save |

|---|