Threaded Coupling Elements

ROEMHLED F9.430 Threaded Coupling Elements

- Maximum operating pressure 500 bar

- Nominal diameter: ND 3 - 5

- Maximum flow rate: 9 - 15 l/min

- Coupling stroke: 4.5 mm

- Maximum coupling force 4.0 - 7.8 kN

- Positioning tolerance, axial: +0.5 mm

- Positioning tolerance, radial: ±0.1 - 0.2 mm

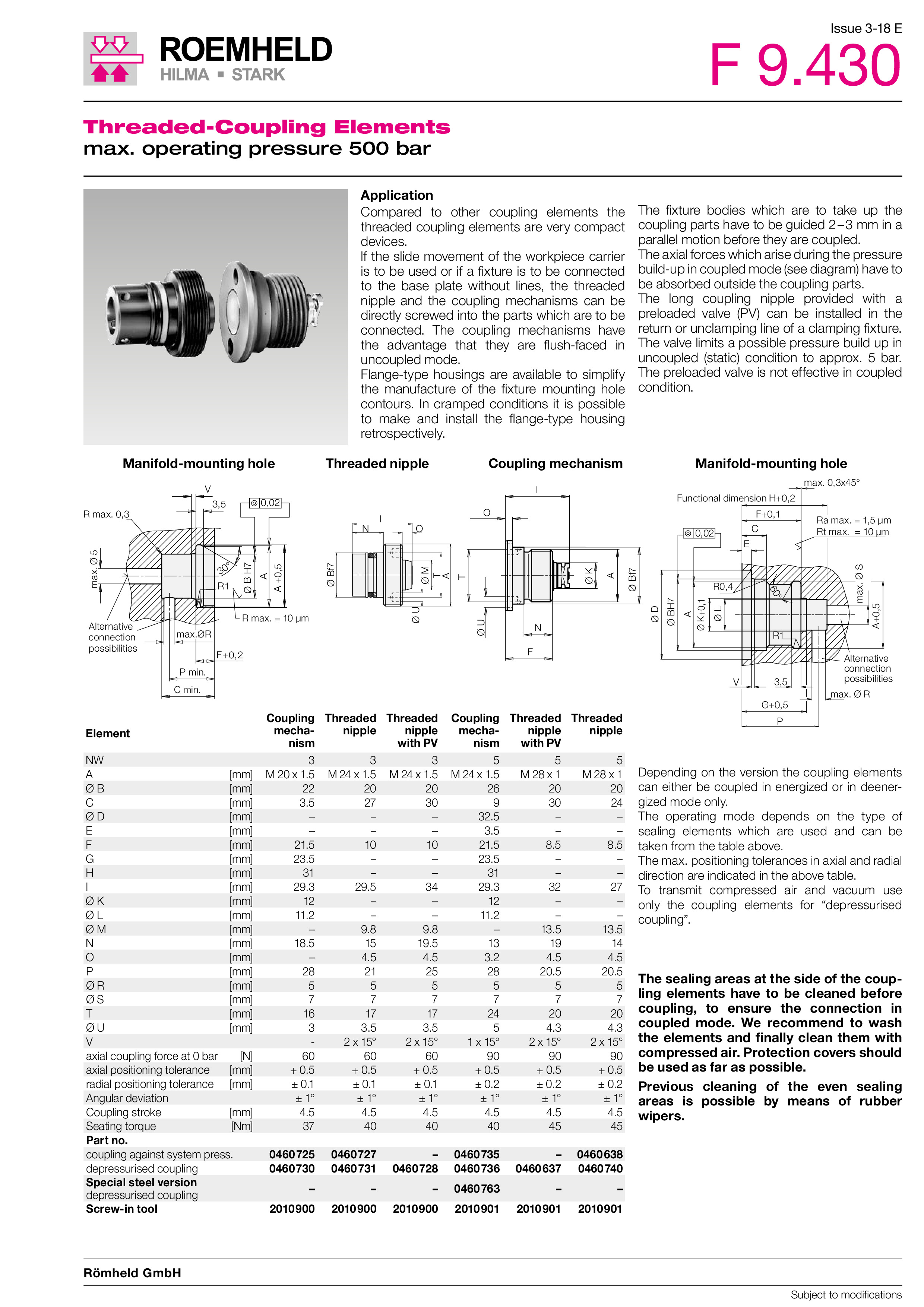

Compared to other coupling elements the threaded coupling elements are very compact devices. lf the slide movement of the workpiece carrier is to be used or if a fixture is to be connected to the base plate without lines, the threaded nipple and the coupling mechanisms can be directly screwed into the parts which are to be connected. The coupling mechanisms have the advantage that they are flush-faced in uncoupled mode.

Threaded Coupling Elements - ROEMHLED F9.430

- Max. operating pressure 500 bar

- Nominal diameter: ND 3 - 5

- Max. flow rate: 9 - 15 l/min

- Coupling stroke: 4.5 mm

- Max. coupling force 4.0 - 7.8 kN

- Positioning tolerance, axial: +0.5 mm

- Positioning tolerance, radial: ±0.1 - 0.2 mm

Application:

Compared to other coupling elements the threaded coupling elements are very compact devices. lf the slide movement of the workpiece carrier is to be used or if a fixture is to be connected to the base plate without lines, the threaded nipple and the coupling mechanisms can be directly screwed into the parts which are to be connected. The coupling mechanisms have the advantage that they are flush-faced in uncoupled mode. Flange-type housings are available to simplify the manufacture of the fixture mounting hole contours. In cramped conditions it is possible to make and install the flange-type housing retros pectively.

The fixture bodies which are to take up the coupling parts have to be guided 2 – 3 mm in a parallel motion before they are coupled. The axial forces which arise during the pressure build-up in coupled mode have to be absorbed outside the coupling parts. The threaded nipples, which are installed into the tank lines, are equipped with a pre-loaded valve (VSV). The pre-loaded valve limits a possible pressure build-up in the return line to approx. 5 bar by causing internal leakage in the hydraulic clamping elements. In coupled mode the pre-loaded valve is not effective.

Depending on the version the coupling elements can either be coupled in energized or in deenergized mode only. The operating mode depends on the type of sealing elements which are used and can be taken from the table above. The max. positioning tolerances in axial and radial direction are indicated in the above table. To transmit compressed air and vacuum use only the coupling elements for “depressurised coupling”.

| Quantity | Unit discount | You Save |

|---|