Hinge Clamps 70 bar with Throttle Valve

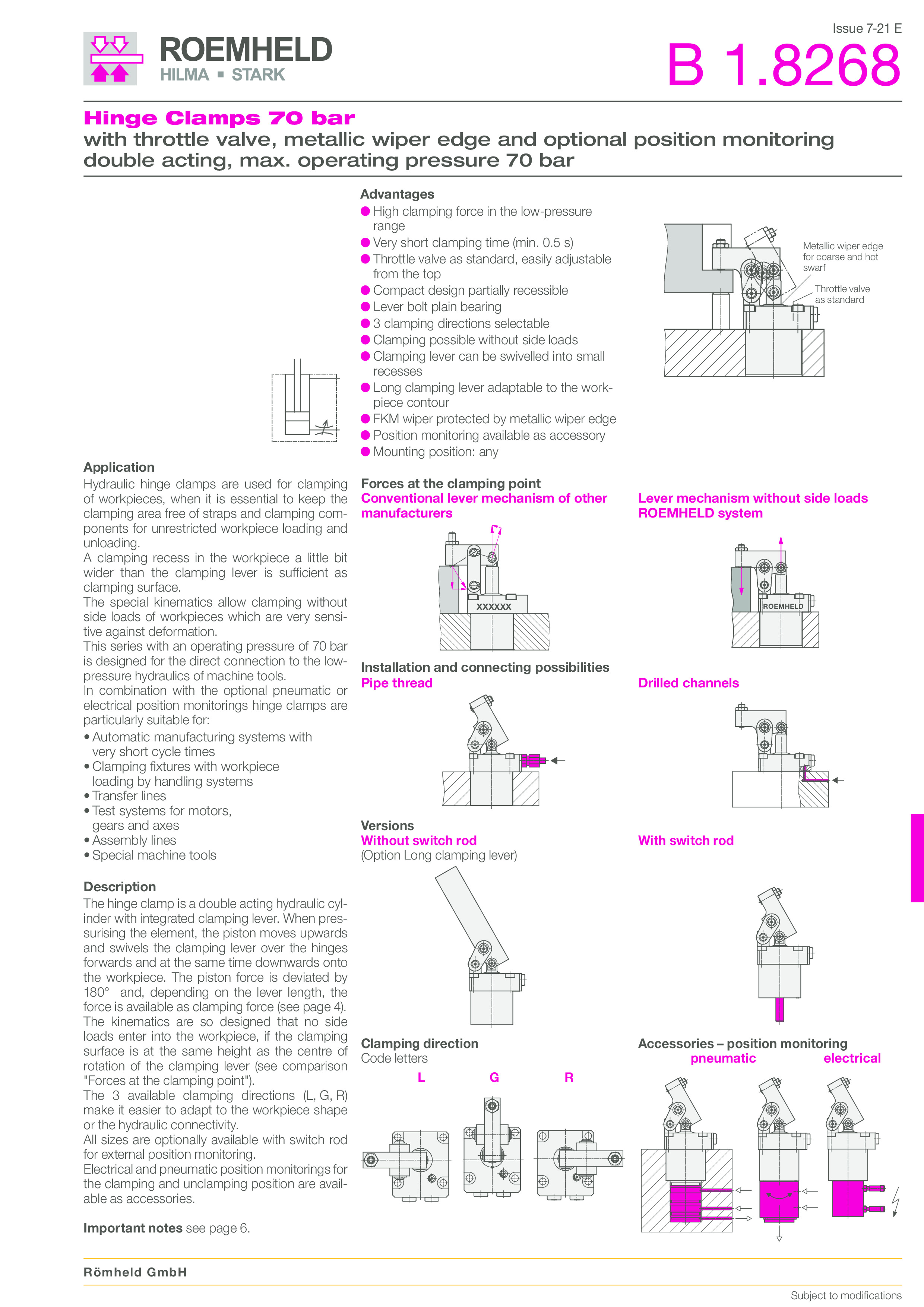

ROEMHELD B1.8268 Hinge Clamps 70 bar: with throttle valve, metallic wiper edge and optional position monitoring double acting

- Maximum operating pressure 70 bar

- Maximum clamping force: 2,6 - 12,1 kN - 1.3

- Maximum clamping force: 2.1 - 4.1 mm

- Adm. flow rate: 16 - 150 cm³/s

The hinge clamp is a double acting hydraulic cylinder with integrated clamping lever. When pressurising the element, the piston moves upwards and swivels the clamping lever over the hinges forwards and at the same time downwards onto the workpiece. The piston force is deviated by 180° and, depending on the lever length, the force is available as clamping force.

Hinge Clamps 70 bar with Throttle Valve - ROEMHELD B1.8268

- Max. operating pressure 70 bar

- Max. clamping force: 2,6 - 12,1 kN - 1.3

- Max. clamping force: 2.1 - 4.1 mm

- Adm. flow rate: 16 - 150 cm³/s

Advantages:

- High clamping force in the low-pressure range

- Very short clamping time (min. 0.5 s)

- Throttle valve as standard, easily adjustable from the top

- Compact design partially recessible

- Lever bolt plain bearing

- 3 clamping directions selectable

- Clamping possible without side loads

- Clamping lever can be swivelled into small recesses

- Long clamping lever adaptable to the workpiece contour

- FKM wiper protected by metallic wiper edge

- Position monitoring available as accessory

- Mounting position: any

Description:

The hinge clamp is a double acting hydraulic cylinder with integrated clamping lever. When pressurising the element, the piston moves upwards and swivels the clamping lever over the hinges forwards and at the same time downwards onto the workpiece. The piston force is deviated by 180° and, depending on the lever length, the force is available as clamping force. The kinematics are so designed that no side loads enter into the workpiece, if the clamping surface is at the same height as the centre of rotation of the clamping lever. The 3 available clamping directions make it easier to adapt to the workpiece shape or the hydraulic connectivity. All sizes are optionally available with switch rod for external position monitoring. Electrical and pneumatic position monitorings for the clamping and unclamping position are available as accessories.

Application:

Hydraulic hinge clamps are used for clamping of workpieces, when it is essential to keep the clamping area free of straps and clamping components for unrestricted workpiece loading and unloading. A clamping recess in the workpiece a little bit wider than the clamping lever is sufficient as clamping surface. The special kinematics allow clamping without side loads of workpieces which are very sensitive against deformation. This series with an operating pressure of 70 baris designed for the direct connection to the lowpressure hydraulics of machine tools. In combination with the optional pneumatic or electrical position monitorings hinge clamps are particularly suitable for:

- Automatic manufacturing systems with very short cycle times

- Clamping fixtures with workpiece loading by handling systems

- Transfer lines

- Test systems for motors, gears and axes

- Assembly lines

- Special machine tools

| Quantity | Unit discount | You Save |

|---|