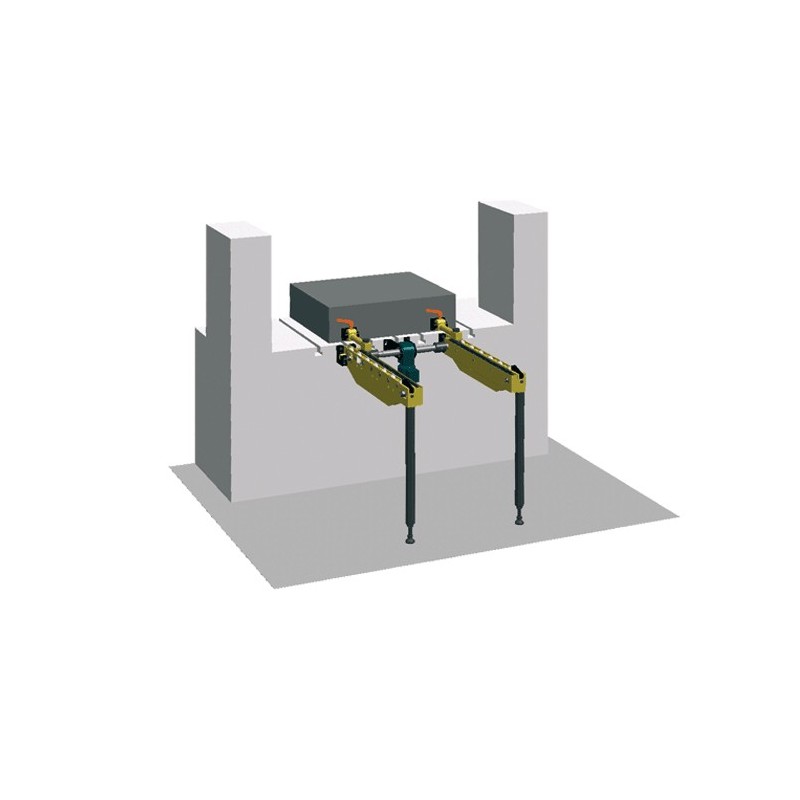

Driven Die Changing Station

HILMA WZ 8.18353 Electrically-Driven Die Changing Station with easy installation suitable for retrofitting and new constructions

- With a special pull push drive and a max. die weight of 250 kN

Electrically Driven Die Changing Station - HILMA WZ 8.18353

- With a special pull push drive and a max. die weight of 250 kN

Special features:

Besides the reduction of non-productive set-up time, the die changing system offers further decisive

Benefits to the user:

- Maximization of profits due to less downtime

- Smaller production batches are possible due to shorter set-up times

- Greater safety for man and machine

- Safe and accident-free handling of dies with less effort, thus creating a more humanised place of work

Description:

The cost-effective drive system has been developed on the basis of standard die consoles and can be easily installed as it requires only little space. Thus, it is very suitable for both retrofitting and new constructions. The drive unit and the carrying console are hung in hooks provided on the press for this purpose and then locked. The die is deposited on the consoles using a crane or a forklift truck. After the die has been deposited, it can be connected to the changing station by means of a pushand- pull system.

The integral chain drive system allows the user automatic die loading and positioning, just by depressing a pushbutton on a separate remote control pendant.

During a die change, the press bed is free, i.e. the pushand- pull elements do not project over the press bed. Furthermore the rear side of the press is completely free. This changing station is suitable for almost any press, can be easily removed and is easy to handle.

If you can’t find what you are looking for, need product pricing, delivery, technical support or associated services CONTACT HYQUIP or call our sales office +44 (0)1204 699959

| Quantity | Unit discount | You Save |

|---|