Coupling Elements

ROEMHELD F9.428 Threaded-body and Built-in type Coupling Elements.

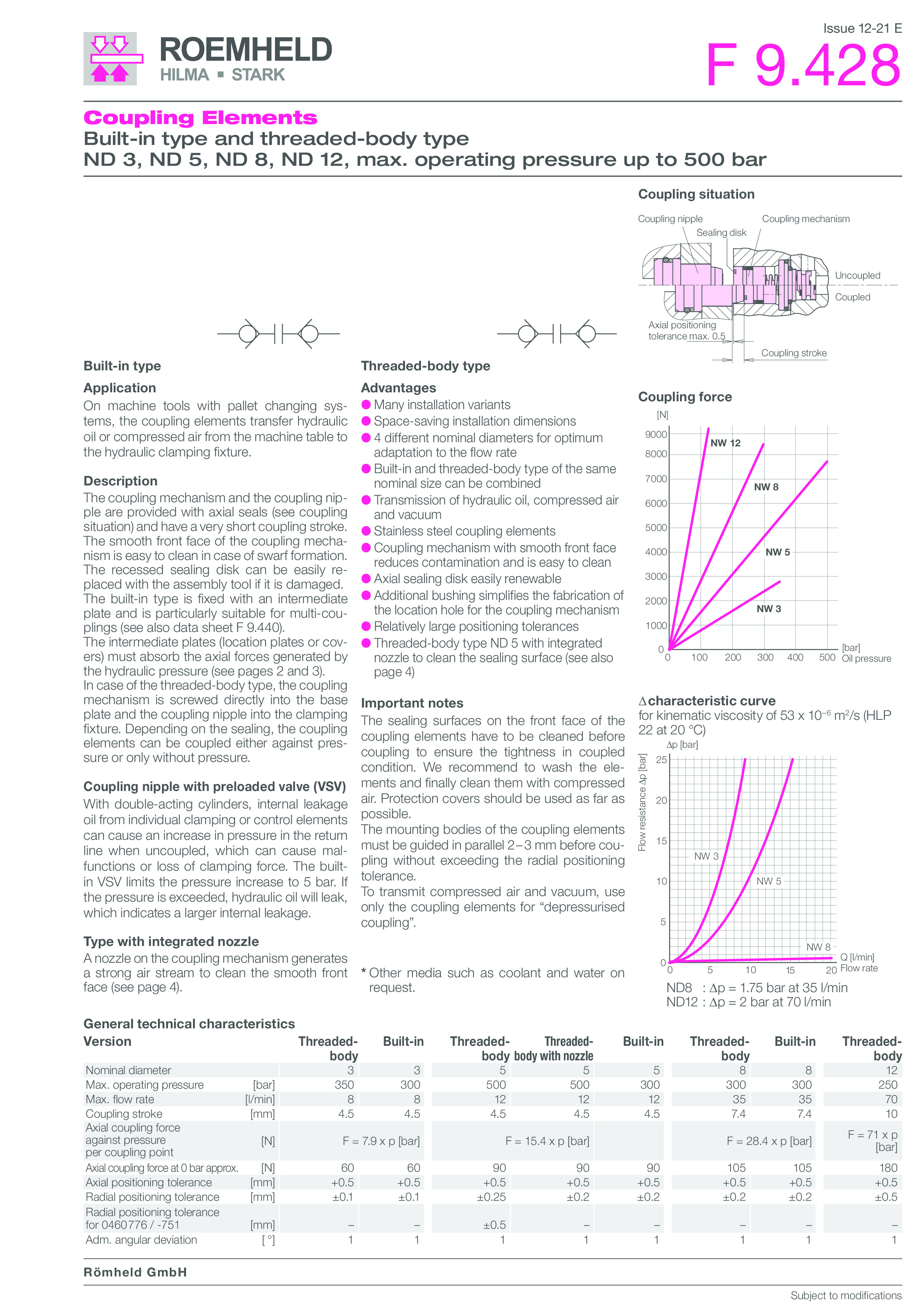

- Nominal diameter: ND 3 - 8

- Max. flow rate: 8 - 35 l/min

- Coupling stroke: 4.5 - 7.4 mm

- Max. coupling force: 2.4 - 8.4 kN

- Positioning tolerance, axial: +0.5 mm

- Positioning tolerance, radial: ±0.1 - 0.25 mm

- Max. operating pressure 300/500 bar

Coupling Elements - ROEMHELD F9.428

- Nominal diameter: ND 3 - 8

- Max. flow rate: 8 - 35 l/min

- Coupling stroke: 4.5 - 7.4 mm

- Max. coupling force: 2.4 - 8.4 kN

- Positioning tolerance, axial: +0.5 mm

- Positioning tolerance, radial: ±0.1 - 0.25 mm

- Max. operating pressure 300/500 bar

Advantages:

- Coupling elements made of stainless steel

- Only minimum installation dimensions required due to space-saving exterior dimensions

- Three different nominal diameters for optimum adaptation to the flow rate

- Transmission of hydraulic oil, compressed air and vacuum

- Large axial and radial positioning tolerances

- Flush-faced coupling mechanism, thereby reduced danger of contamination and simple cleaning

- Simple fabrication of the location hole for the coupling mechanism by additional bushing

- Threaded-body type with integrated nozzle for cleaning of sealing surfaces

- Large selection of variants

Application:

Coupling elements are used in order to transmit liquid or gaseous media as hydraulic oil or compressed air e.g. in machine tool machines with pallet transfer systems from the machine tool table to the fixture. Due to their compact exterior dimensions these couplings can very well be integrated in fixture designs.

Description:

Coupling mechanism and coupling nipple are provided with axial seals. This results in a very short coupling stroke as well as a smooth front face of the coupling mechanism and thereby only little area of attack by dirt and swarf. The built-in types are designed for mounting in plates and are particularly suitable for the use in multi-couplings (see also data sheet F 9.440)

The threaded-body types can be screwed in directly in the fixture body and are therefore optimum line connections between two components as e.g. basic fixture and changing fixture. The axial forces generated in the coupling situation have to be compensated externally positively or non-positively. According to the version the coupling elements can be coupled and uncoupled against pressure or only in depressurised mode (depending on the sealing material). The long coupling nipple provided with a preloaded valve (PV) can be installed in the return or unclamping line of a clamping fixture. The valve limits a possible pressure build up in uncoupled (static) condition to approx. 5 bar. The preloaded valve is not effective in coupled condition.

If you can’t find what you are looking for, need product pricing, delivery, technical support or associated services CONTACT HYQUIP or call our sales office +44 (0)1204 699959

| Quantity | Unit discount | You Save |

|---|