Fixture Clamps for Concentric Clamping

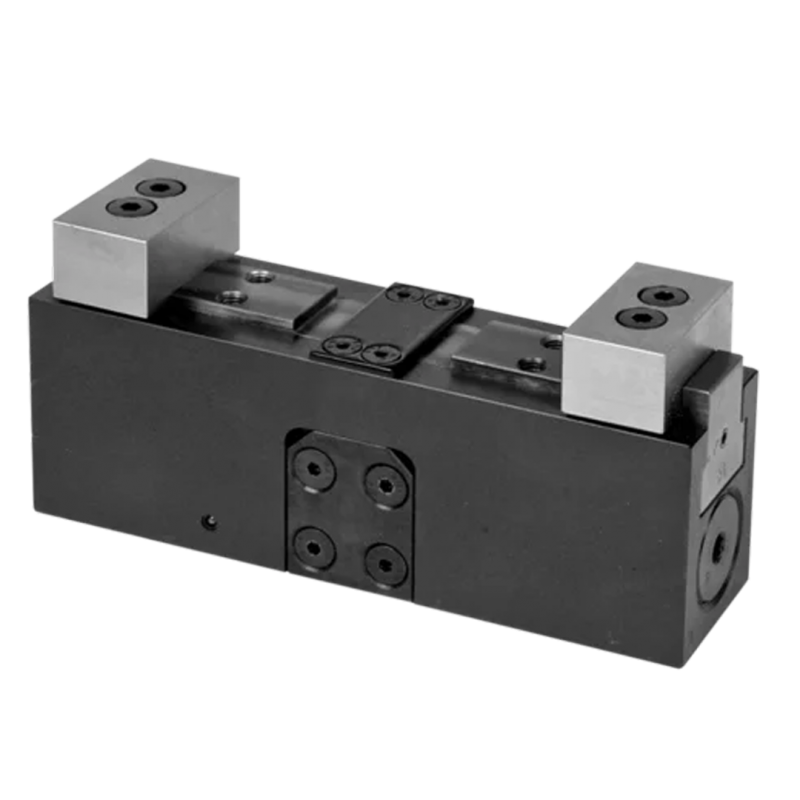

ROEMHELD I4.120 Fixture clamp, concentric clamping: max. clamping force 6.5 kN and 9 kN, jaw width 40 and 65 mm double acting

- Maximum operating pressure 250 bar

- Maximum clamping force: 6.5 - 9 kN/jaw

- Max. retention force: 8 - 15 kN

- Jaw width: 40 - 65 mm

- Clamping stroke: 2x5 - 2x8 mm

- Maximum flow rate: 70 - 100 cm³/s

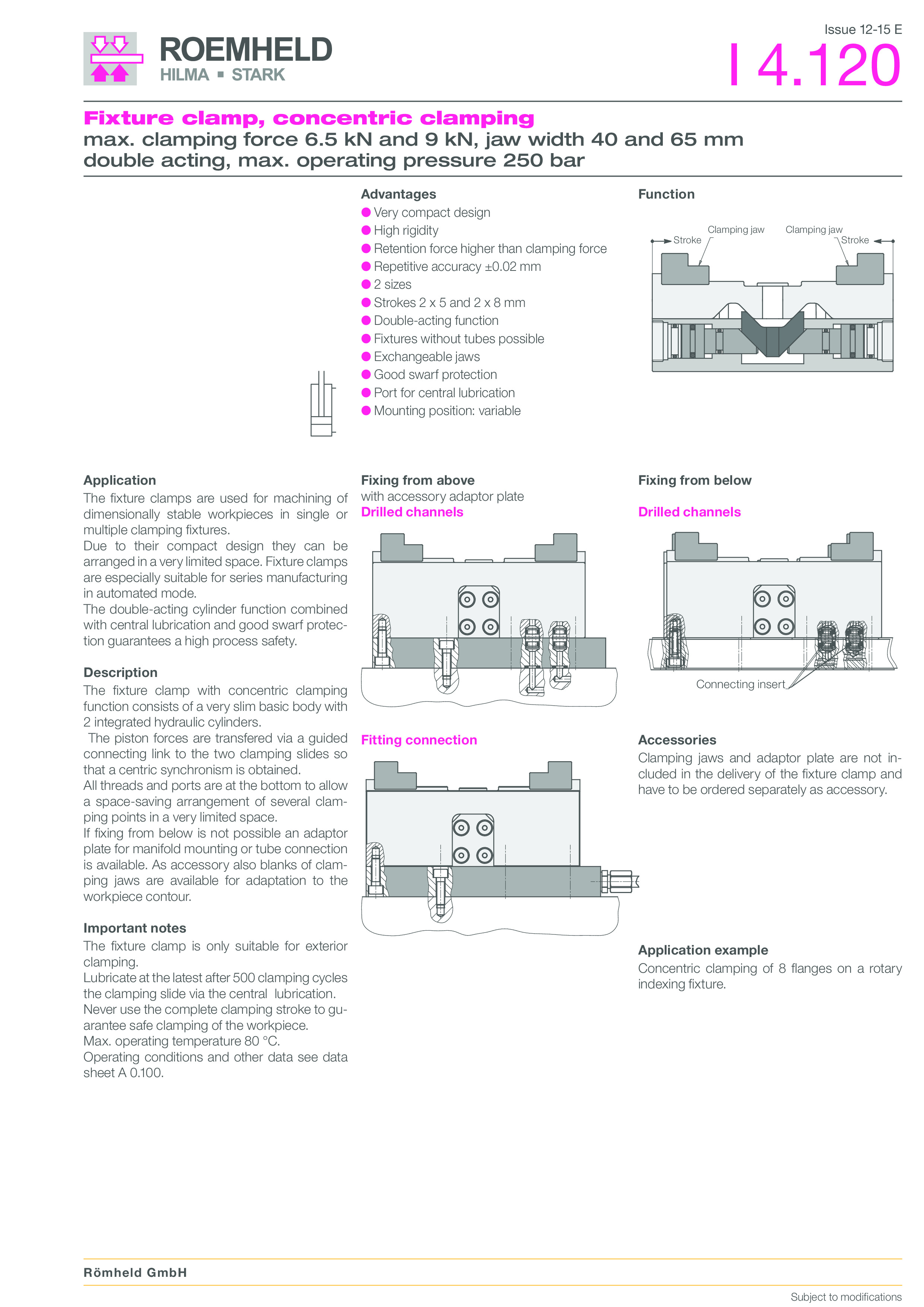

The fixture clamp with concentric clamping function consists of a very slim basic body with 2 integrated hydraulic cylinders. The piston forces are transferred via a guided connecting link to the two clamping slides so that a centric synchronism is obtained. All threads and ports are at the bottom to allow a space-saving arrangement of several clamping points in a very limited space.

Fixture Clamps for Concentric Clamping - ROEMHELD I4.120

- Max. operating pressure 250 bar

- Max. clamping force: 6.5 - 9 kN/jaw

- Max. retention force: 8 - 15 kN

- Jaw width: 40 - 65 mm

- Clamping stroke: 2x5 - 2x8 mm

- Max. flow rate: 70 - 100 cm³/s

Advantages:

- Very compact design

- High rigidity

- Retention force higher than clamping force

- Repetitive accuracy ±0.02 mm

- 2 sizes

- Strokes 2 x 5 and 2 x 8 mm

- Double-acting function

- Fixtures without tubes possible

- Exchangeable jaws

- Good swarf protection

- Port for central lubrication

- Mounting position: variable

Application:

The fixture clamps are used for machining of dimensionally stable workpieces in single or multiple clamping fixtures. Due to their compact design they can be arranged in a very limited space. Fixture clamps are especially suitable for series manufacturing in automated mode. The double-acting cylinder function combined with central lubrication and good swarf protection guarantees a high process safety.

Description:

The fixture clamp with concentric clamping function consists of a very slim basic body with 2 integrated hydraulic cylinders. The piston forces are transferred via a guided connecting link to the two clamping slides so that a centric synchronism is obtained. All threads and ports are at the bottom to allow a space-saving arrangement of several clamping points in a very limited space. If fixing from below is not possible an adaptor plate for manifold mounting or tube connection is available. As accessory also blanks of clamping jaws are available for adaptation to the workpiece contour.

| Quantity | Unit discount | You Save |

|---|