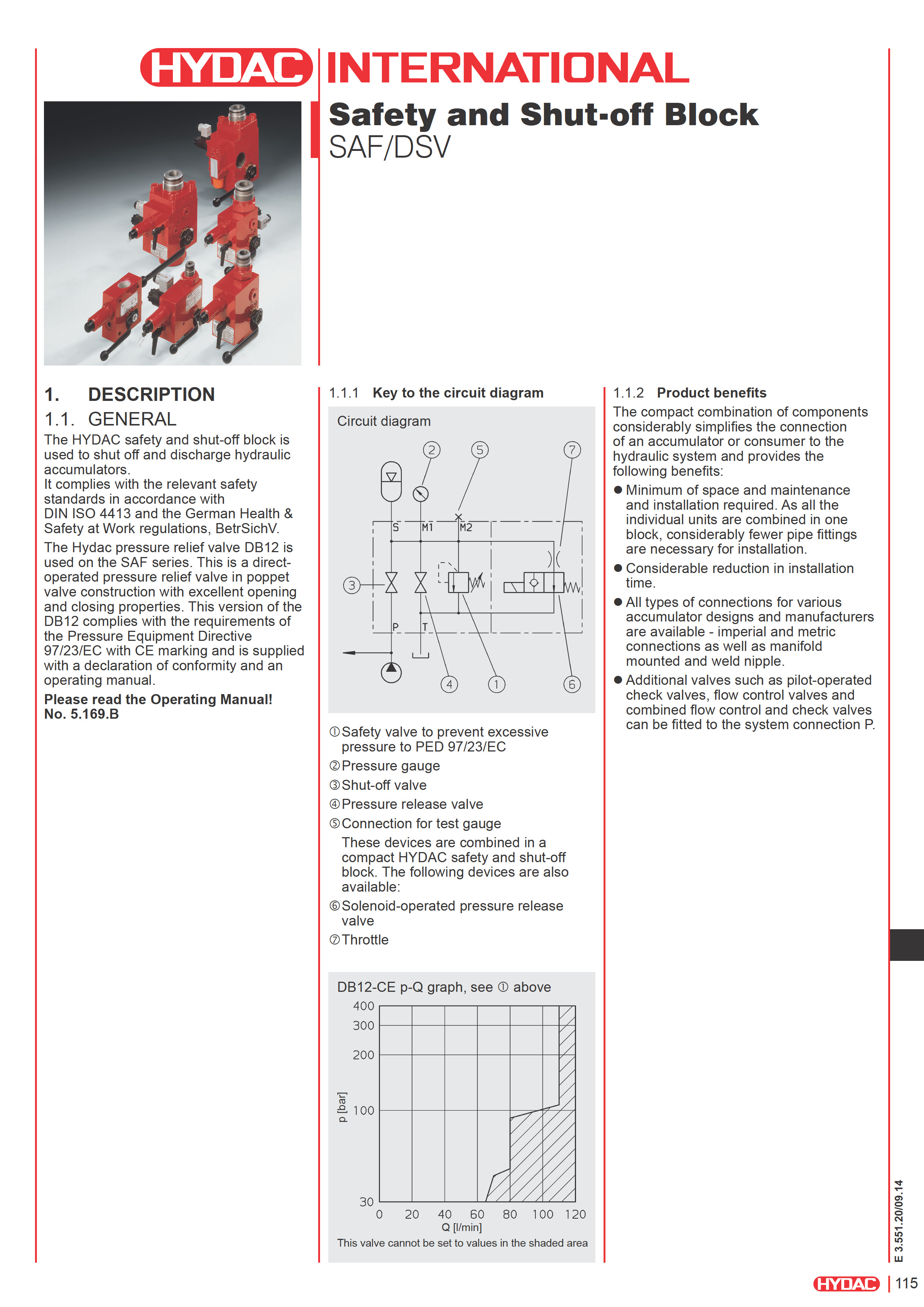

Hydac 3-Way safety and Shut-Off Block SAF /DSV

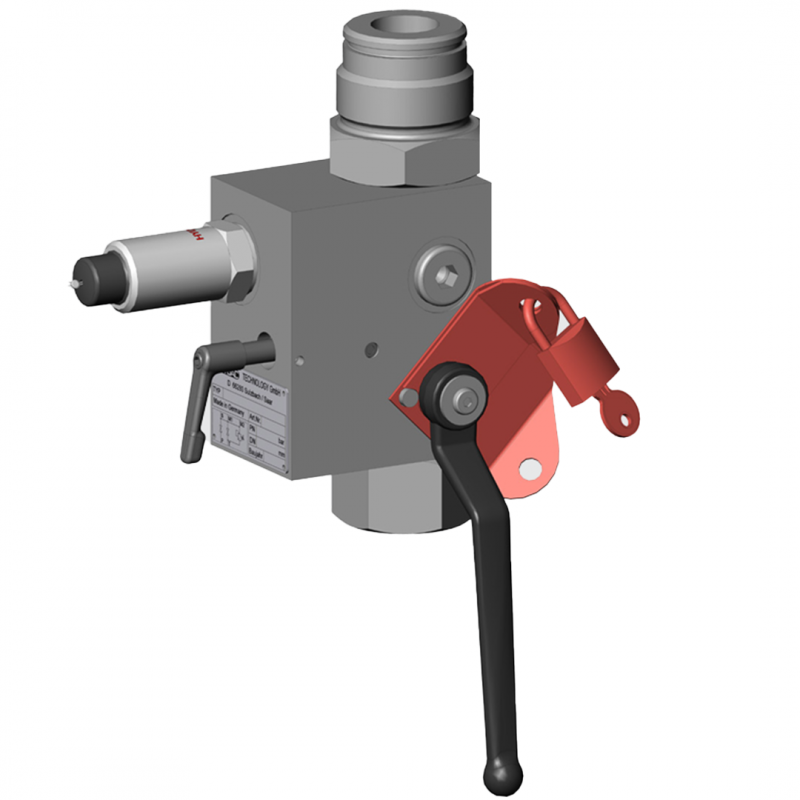

The HYDAC SAF/DSV 3-Way Safety and Shut-Off Blocks are compact, high-pressure units (up to 400 bar) designed for safely isolating and discharging hydraulic accumulators or consumers. Compliant with DIN EN 982 and German safety regulations, the SAF series combines multiple functions in one block, reducing installation time and space requirements. The simpler DSV10 version offers essential shut-off functionality in a smaller form.

Key Features:

- Space-saving design replaces multiple fittings, reducing installation time

- Available with manual or solenoid actuation, limit switches, and pressure relief valve lock

- Compatible with various accumulator types and connection styles (imperial, metric, manifold, weld nipple)

HYDAC 3-Way safety and Shut-Off Block SAF/DSV

SAF...M(E)...

- NG = 10 / 20 / 32 / 50

- pmax = 400 bar

- manual and/or solenoid-operated discharged

- optional with inductive proximity switch or mechanical limit switch and/or pressure release valve lock

DSV10...

- NG = 10

- pmax = 350 bar

- simpler version of the SAF 10

General Function:

The HYDAC safety and shut-off block is used to shut off and discharge hydraulic accumulators or consumers. It complies with the relevant safety standards in accordance with DIN EN 982 and the German industrial safety regulations BetrSichV.

The Hydac pressure relief valve DB12 is used on the SAF series. This is a direct operated pressure relief valve in poppet valve construction with excellent opening and closing characteristics. This version of the DB12 complies with the requirements of the Pressure Equipment Directive 97/23/EC with CE marking and is supplied with a declaration of conformity and an operating manual.

Features:

- Minimum of space, maintenance and installation required. As all the individual units are combined in one block, considerably fewer pipe fittings are necessary for installation

- Considerable reduction in installation time

- All types of connections for various accumulator designs and makes are available – imperial and metric connections, as well as a manifold, mounted and weld nipple

- Additional valves such as pilot-operated check valves, flow control valves and combined flow control and check valves can be fitted to the system connection P

Specifications:

- Minimum of space and maintenance

- Minimum of installation required (1 SAF replaces as a rule up to 10 individual pipe connections)

- Considerable reduction of installation time

- Adapters for various accumulator types and

- Additional valves (pilot-operated check valves, flow control valves, etc)

| Quantity | Unit discount | You Save |

|---|