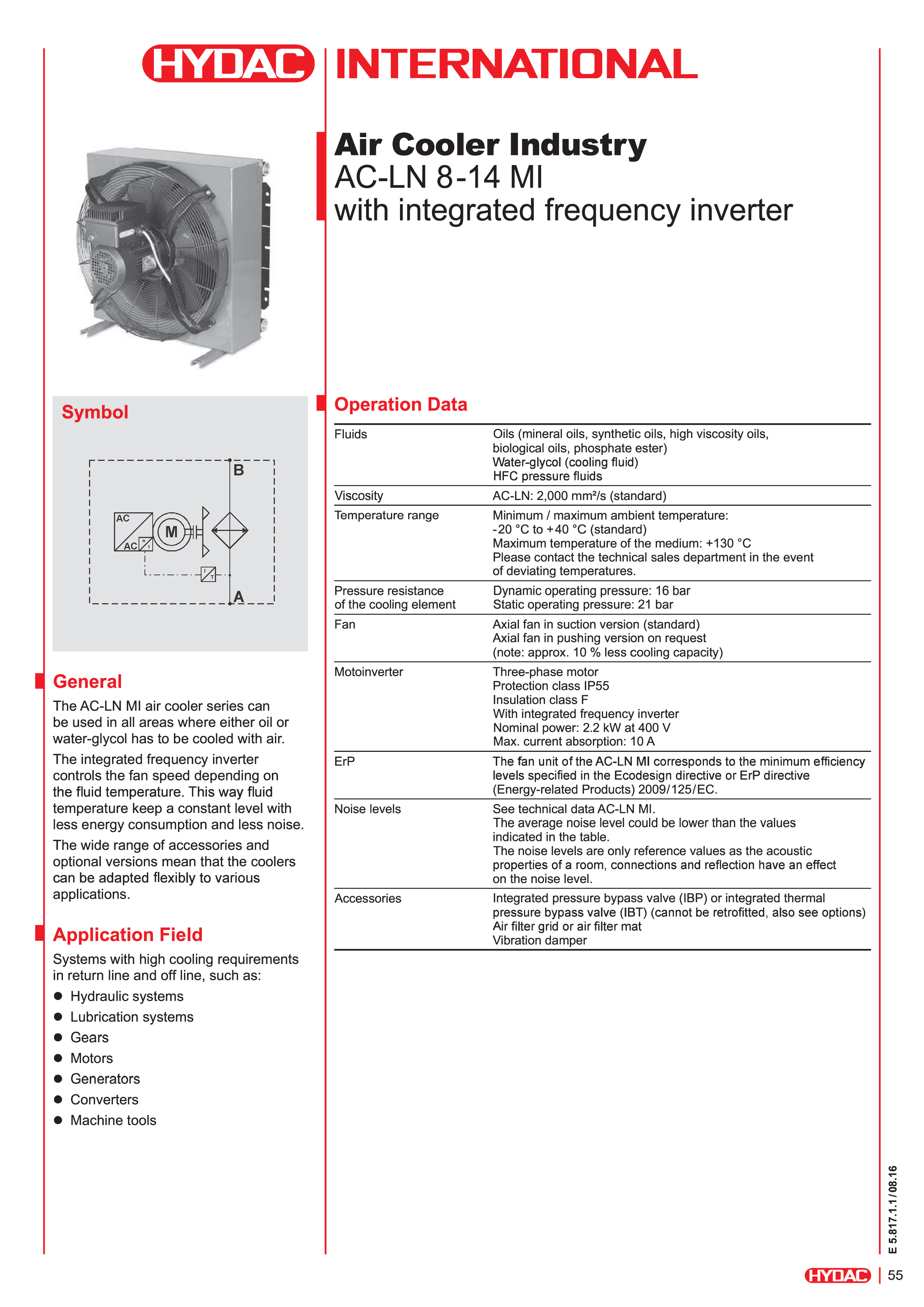

Hydac Oil / Air Cooler Units AC-LN MI Low Noise Series

The HYDAC Oil/Air Cooler Units AC-LN MI Low Noise Series offer energy-efficient, intelligent cooling with variable fan speed controlled by an integrated frequency inverter. Designed for applications with high cooling demands, they ensure consistent fluid temperature, reduced power consumption, and quieter operation.

Key Features:

- Variable-speed axial fan with integrated frequency inverter

- Plug-and-play design with built-in temperature probe (PT1000)

- Lower operating costs and noise levels

HYDAC Oil / Air Cooler Units AC-LN MI Low Noise Series

The integrated frequency inverter controls the fan speed depending on the fluid temperature. This way fluid temperature keep a constant level with less energy consumption and less noise

AC-LN MI coolers use high efficiency axial fans driven by a frequency inverter. This guarantees immediate adjustment to required cooling performance under changing load conditions

Variable speed

The inverter controls the fan speed in order to have a constant temperature

Plug and Play

Simple installation thanks to the integrated frequency inverter and temperature probe

Lower operating cost

The electric power is required only when cooling power is needed allowing lower power consumption

Lower average noise level

When less power is required the cooler generates less noise

PT1000 Temperature probe with probe holder

Accurate and reliable temperature measurement, no need to drain the cooling system when probe replacement is needed

Fail-Safe operation

Operation at maximum speed in case of Probe failure detection (open or short circuit)

Own safety

If during operation the electronic overheats, fan speed drops automatically

Software interface

A user friendly interface is available to check and modify all the parameters directly on site

Typical Applications include systems with high cooling requirements in return line and off line, such as:

- Hydraulic systems

- Lubrication systems

- Gears

- Motors

- Generators

- Converters

- Machine tools

Efficient cooling systems can help to lengthen the service life of the operating fluids and filters used and reduce life cycle costs

| Quantity | Unit discount | You Save |

|---|