Hydro-pneumatic Pump Units - ROEMHELD D8.602

ROEMHELD D8.602 Hydro-pneumatic pump units for single and double acting cylinders

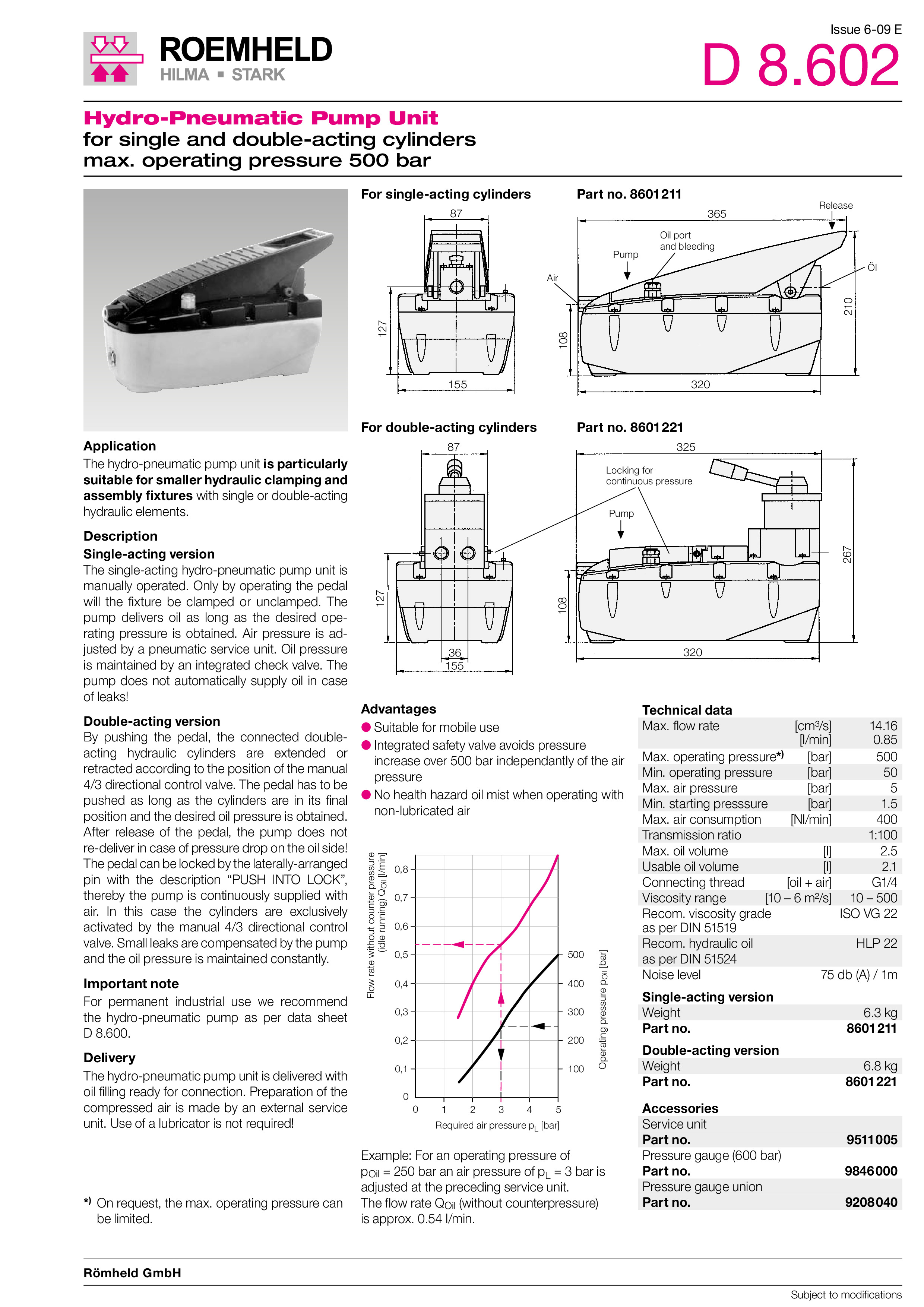

- Flow rate: 0.85 l/min

- Minimum operating pressure: 50 bar

- Maximum air pressure: 5 bar

- Maximum air consumption 400 l/min

- Intensification ratio: 1:100

- Reservoir volume: approx. 2.5 l

- Usable oil volume: approx. 2.1 l

- Hydraulic connection: G 1/4

- Single and Double-Acting versions available

This hydro-pneumatic pump unit is particularly suitable for smaller hydraulic clamping and assembly fixtures with single or double-acting hydraulic elements.

Hydro-pneumatic Pump Units - ROEMHELD D8.602

- Flow rate: 0.85 l/min

- Min. operating pressure: 50 bar

- Max. air pressure: 5 bar

- Max. air consumption 400 l/min

- Intensification ratio: 1:100

- Reservoir volume: approx. 2.5 l

- Usable oil volume: approx. 2.1 l

- Hydraulic connection: G 1/4

- Single and Double-Acting versions available

Application:

The hydro-pneumatic pump unit is particularly suitable for smaller hydraulic clamping and assembly fixtures with single or double-acting hydraulic elements.

Single-acting version

The single-acting hydro-pneumatic pump unit is manually operated. Only by operating the pedal will the fixture be clamped or unclamped. The pump delivers oil as long as the desired operating pressure is obtained. Air pressure is adjusted by a pneumatic service unit. Oil pressure is maintained by an integrated check valve. The pump does not automatically supply oil in case of leaks!

Double-acting version

By pushing the pedal, the connected doubleacting hydraulic cylinders are extended or retracted according to the position of the manual 4/3 directional control valve. The pedal has to be pushed as long as the cylinders are in its final position and the desired oil pressure is obtained. After release of the pedal, the pump does not re-deliver in case of pressure drop on the oil side! The pedal can be locked by the laterally-arranged pin with the description “PUSH INTO LOCK”, thereby the pump is continuously supplied with air. In this case the cylinders are exclusively activated by the manual 4/3 directional control valve. Small leaks are compensated by the pump and the oil pressure is maintained constantly.

| Quantity | Unit discount | You Save |

|---|