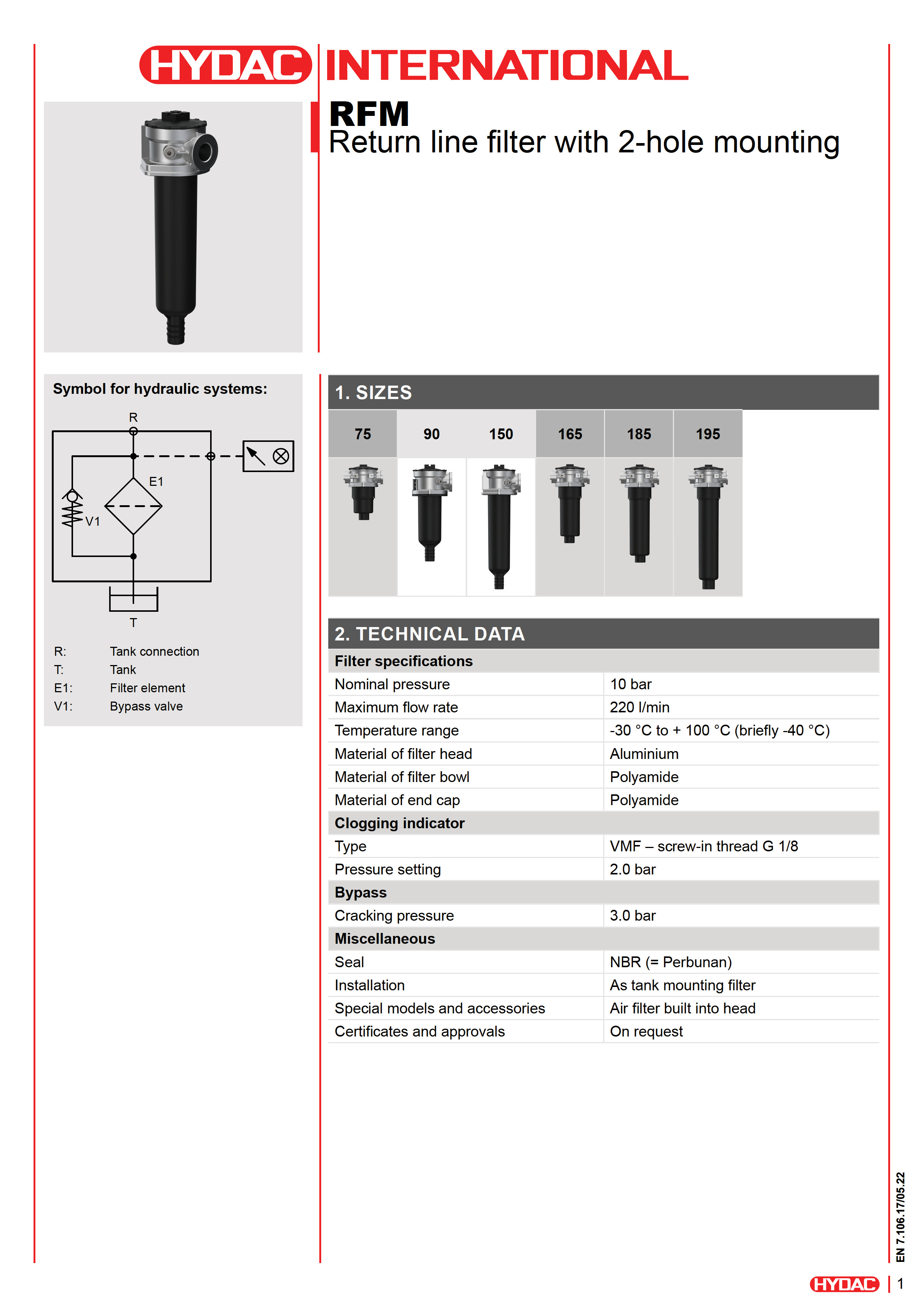

Hydac Return Line Filter with 2-hole Mounting RFM

HYDAC RFM Return Line Filters with 2-Hole Mounting are compact, lightweight solutions for efficient filtration of hydraulic fluids in both tank-mounted and in-tank configurations. With flow capacities up to 2,600 l/min and pressure handling up to 10 bar, RFM filters are ideal for mobile and space-restricted applications, ensuring clean return oil and reliable system operation.

Key Features:

- Flow rates up to 200 l/min (tank mounted versions) or up to 2600 l/min (in-tank versions)

- Pressure levels up to 10 bar

- Connections: G½ to SAE DN 65

HYDAC Return Line Filters with 2 Hole Mounting RFM

- Flow rates up to 200 l/min (tank mounted versions) or up to 2600 l/min (in-tank versions)

- Pressure levels up to 10 bar

- Connections: G½ to SAE DN 65

- Installation sizes: 75, 90, 150, 165, 185, 210, 270, 330, 500, 600, 661, 851

Filter Specifications:

- Nominal pressure 10 bar

- Temperature range -30°C to +100°C (short-term: -40°C)

- Type of clogging indicator: VMF connection thread G 1/8 (return line indication)

- Pressure setting of clogging indicator: 2 bar (others on request)

- Bypass cracking pressure: 3 bar (others on request)

General Function:

RFM return line filters can be installed as a tank mounted or as a in-tank filter for filtration of solids from hydraulic fluids. Prevents dangerous malfunctions in hydraulic components as a result of excessive back pressure in the return line. The lightweight and compact design makes it especially suitable for mobile applications. RFM filters are constructed of aluminium filter head (with 2 hole flange), polymide plastic filter bowl and a screw-on cover plate. Return line filters can be fitted with breather filters as additional equipment.

RFM return line, In-tank filter versions have a Unique design which allows the RFM filter to be installed completely inside of the reservoir tank. This saves space, protects the filter, reduces leak points and reduces overall installation cost. The Lightweight unit requiring no filter head reduces pressure drop while decreasing cost which is an excellent option for low overhead clearance applications. All elements available for RFM filters have the bypass valve built into the filter element. As a result, a new bypass valve is provided each time the element is changed, making it less likely that a bypass valve will stick open, jam, or fail through fatigue.

| Quantity | Unit discount | You Save |

|---|