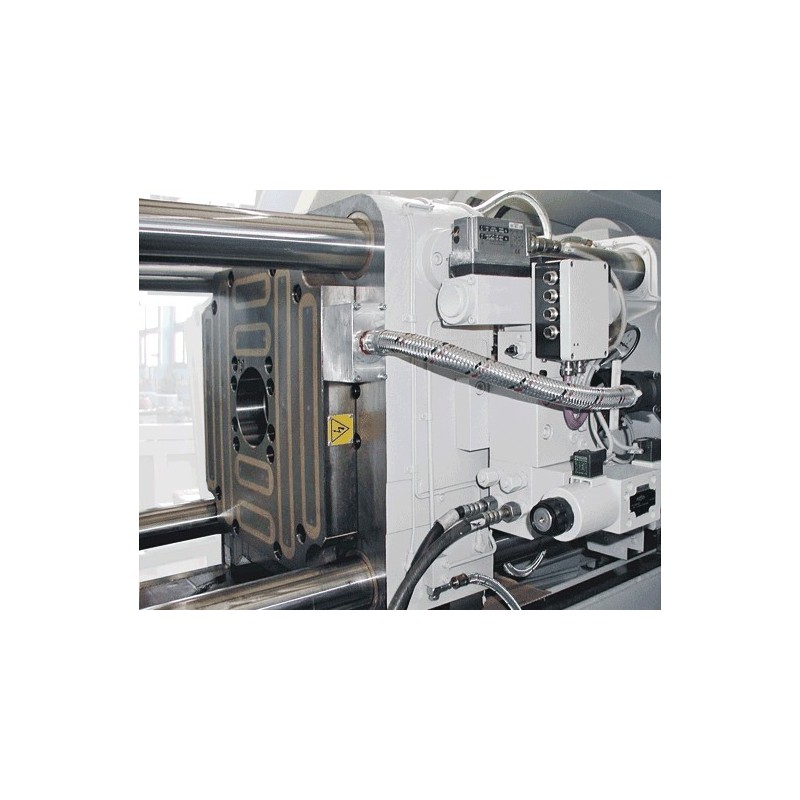

Magnetic Clamping Systems M-TECS 240-D

M-TECS 240-D Hilma Magnetic clamping system for die casting machines

- Max. working temperature: 240°C

- Specific magnetic force: 18 kg/cm² (directly at the pole)

- Effective magnetic force: max 5-12 kg/cm²

- Magnetic penetration depth: 15-20mm

- Plate thickness: 55mm

Magnetic Clamping Systems M-TECS 240-D

- Max. working temperature: 240°C

- Specific magnetic force: 18 kg/cm² (directly at the pole)

- Effective magnetic force: max 5-12 kg/cm²

- Magnetic penetration depth: 15-20mm

- Plate thickness: 55mm

Function and interface of the magnetic clamping system:

The electrical permanent magnet clamping system is firmly kept in place even in the case of a power failure. Electricity is required for just 1 or 2 seconds to first magnetise (clamp) the system. In operation the system works independently of any power source. Only for unclamping is electricity needed again. Magnetic force is generated by a very flat, strong magnetic field. It penetrates the die base plate by just a few millimetres and has therefore no impact on the workpiece. Magnetic forces between 2 and 5 kg/cm² can be attained, which depends on the surface, i.e. the larger the die the higher the magnetic forces. Clamping forces of e.g. 500, 1000 or 2000 kN can be achieved. The forces can be adapted to suit the needs of the machine. The design of the magnetic plates is flexible, and the size and shape can be determined to suit customers' requirements. The plates have thicknesses of about 55mm. Additional holes for ejector, centring rings/positioning pins as well as clearance holes for punchings (metal forming) can be easily integrated into the magnetic plates. There are no limits for the geometrical shape of the magnetic plates. On request, the system is available to work at a maximum temperature of 230°C. It withstands heavy accumulations of dirt, mould separation agents and vacuum. Permanent monitoring of the clamped condition, the temperature and the mould position in automatic operation gives maximum safety

The system consists of two electrical permanent magnet plates, control system, remote control pendant, a complete set of cables, and in most cases it can be installed in a few hours

The interface with the machine is carried out as per EUROMAP 70.0 or 70.1 or, at the customer's request, as a simple no-volt contact to the emergency cut-out or the machine drive

If you can't find what you are looking for, need product pricing, delivery, technical support or associated services CONTACT HYQUIP or call our sales office +44 (0)1204 699959

| Quantity | Unit discount | You Save |

|---|