Threaded Body Work Supports with Metallic Wiper Edge

ROEMHELD B1.9470 Threaded-Body Work Supports: with metallic wiper edge, single acting

- Maximum operating pressure 70 bar

- External thread: M26 - M45

- Maximum load force: 3 - 10 kN

- Plunger diameter: 10 - 16 mm

- Plunger stroke: 6.5 - 10 mm

- Maximum flow rate: 25 cm³/s

- Elastic deformation: 3.5 - 9 μm/kN

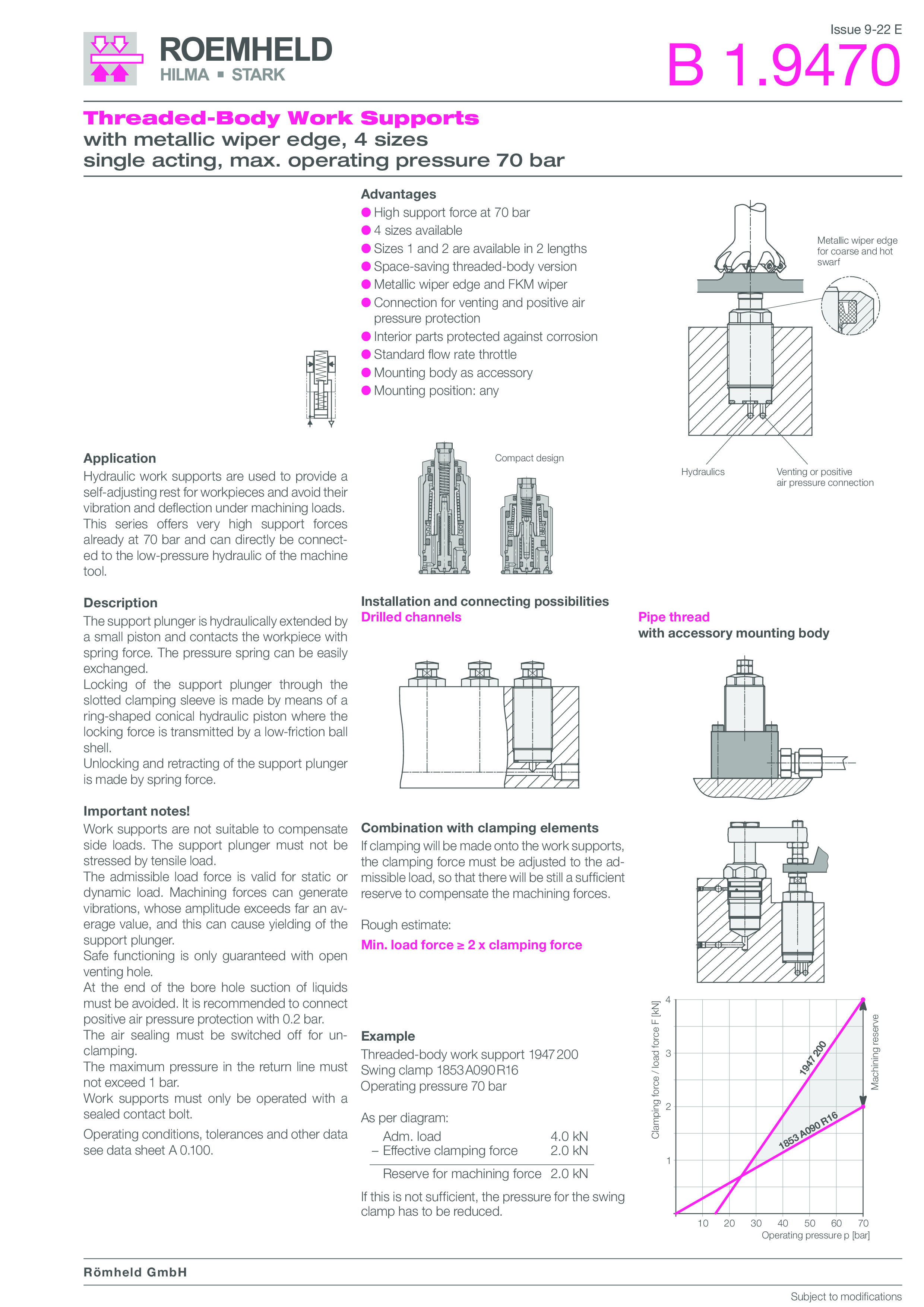

The support plunger is hydraulically extended by a small piston and contacts the workpiece with spring force. The pressure can be easily exchanged. Locking of the support plunger through the slotted clamping sleeve is made by means of a ring-shaped conical hydraulic piston where the locking force is transmitted by a low friction ball shell. Unlocking and retracting of the support plunger is made by spring force.

Threaded Body Work Supports with Metallic Wiper Edge - ROEMHELD B1.9470

- Max. operating pressure 70 bar

- External thread: M26 - M45

- Max. load force: 3 - 10 kN

- Plunger diameter: 10 - 16 mm

- Plunger stroke: 6.5 - 10 mm

- Max. flow rate: 25 cm³/s

- Elastic deformation: 3.5 - 9 μm/kN

Advantages:

- High support force at 70 bar

- 4 sizes available

- Space-saving threaded-body version

- Metallic wiper edge and FKM wiper

- Connection for venting and positive air pressure protection

- Corrosion-resistant interior parts

- Standard flow rate throttle

- Mounting body as accessory

- Mounting position: variable

Application:

Hydraulic work supports are used to provide a self-adjusting rest for the workpiece during the machining operations. They compensate the workpiece surface irregularities, also vibration and deflection under machining loads. This series offers very high support forces already at 70 bar and can directly be connected to the low-pressure hydraulic of the machine tool.

Description:

The support plunger is hydraulically extended by a small piston and contacts the workpiece with spring force. The pressure can be easily exchanged. Locking of the support plunger through the slotted clamping sleeve is made by means of a ring-shaped conical hydraulic piston where the locking force is transmitted by a low friction ball shell. Unlocking and retracting of the support plunger is made by spring force.

| Quantity | Unit discount | You Save |

|---|