Electric Swing Clamps

ROEMHELD B1.8310 Electric Swing Clamps

- Axial pulling force: 3 - 9 kN

- Top flange, with position and clamping force monitoring

- DC voltage 24 V

- Minimum energy demand

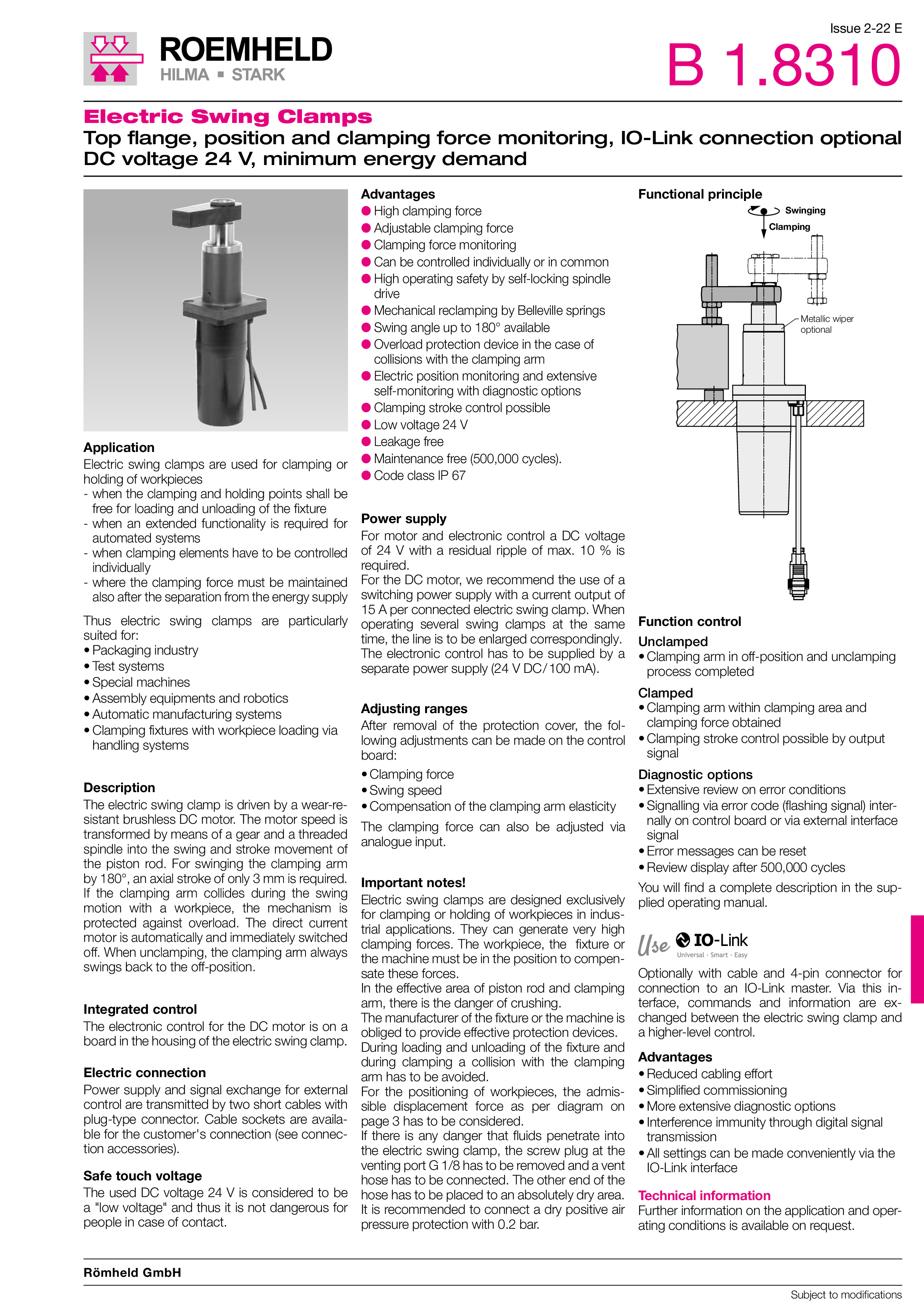

The electric swing clamp is driven by a brushless DC motor. The motor speed is transformed by means of a gear and a threaded spindle into the swing and stroke movement of the piston rod. For swinging the clamping arm by 180°, an axial stroke of only 3 mm is required.

Electric Swing Clamps - ROEMHELD B1.8310

- Axial pulling force: 3 - 9 kN

Advantages:

- High clamping force

- Adjustable clamping force

- Clamping force monitoring (error code output)

- Can be controlled individually or in common

- High operating safety by self-locking spin dle drive

- Mechanical reclamping by Belleville springs

- Swing angle up to 180° available

- Overload protection device in the case of collisions with the clamping arm

- Electric position monitoring and extensive self-monitoring with error message

- Clamping stroke control possible

- Low voltage 24 V

- Leakage free

- Maintenance free (500,000 cycles)

- Code class IP 67

Application:

Electric swing clamps are used for clamping or holding of workpieces:

- where the use of hydraulic clamping elements is not possible

- where the clamping force must be maintained also after the separation from the energy supply

- if clamping elements have to be controlled individually.

- that require freely accessible clamping and holding points for material handling

Thus electric swing clamps are particularly suited for:

- Food industry

- Packaging industry

- Clean room area

- Test systems

- Special machines

- Assembly equipments and robotics

- Automatic manufacturing systems

- Clamping fixtures with workpiece loading via handling systems

Description:

The electric swing clamp is driven by a brushless DC motor. The motor speed is transformed by means of a gear and a threaded spindle into the swing and stroke movement of the piston rod. For swinging the clamping arm by 180°, an axial stroke of only 3 mm is required.

If the clamping arm collides during the swing motion with a workpiece, the mechanism is protected against overload. The direct current motor is automatically and immediately switched off. When unclamping, the clamping arm always swings back to the off-position.

| Quantity | Unit discount | You Save |

|---|