Threaded Body Work Supports with Metallic Wiper Edge M30 x 1.5

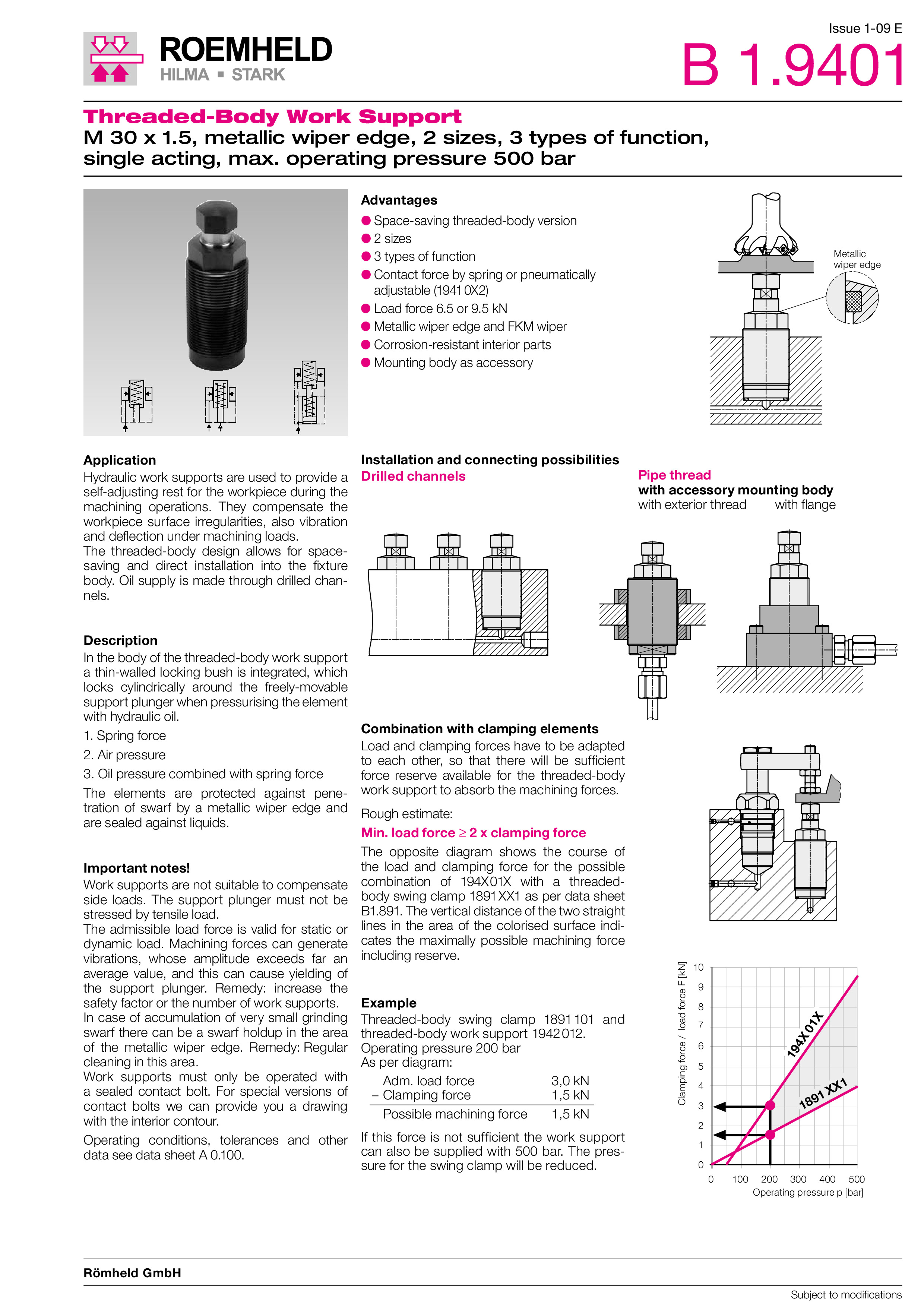

ROEMHELD B1.9401 Threaded Body Work Support: M 30 x 1.5, metallic wiper edge, 2 sizes, 3 types of function, single acting

- Maximum operating pressure 500 bar

- Cross section of the body: 70x48 - 140x105 mm

- Maximum load force: 8 - 40 kN

- Plunger diameter ranges from 16 to 40 mm

- Plunger stroke: 8 - 20 mm

- Maximum flow rate: 25 cm³/s

- Elastic deformation: 0.7 - 1.0 µm/kN

In the body of the threaded-body work support a thin-walled locking bush is integrated, which locks cylindrically around the freely-movable support plunger when pressurising the element with hydraulic oil.

| Part Number | Material Number | Stroke | Type | Admissible Load Force (kN) | Price | Add to Parts List |

|---|---|---|---|---|---|---|

| 1942-012 | 8mm | Oil Pressure Combined with Spring Force | 9.5 | £291.95 £350.34 Inc. VAT |

|

|

| 1940-002 | 8mm | Spring Force | 6.5 | £212.33 £254.79 Inc. VAT |

|

|

| 1940-012 | 8mm | Spring Force | 9.5 | £287.97 £345.56 Inc. VAT |

|

|

| 1941-002 | 8mm | Air Pressure | 6.5 | £226.93 £272.31 Inc. VAT |

|

|

| 1941-012 | 8mm | Air Pressure | 9.5 | £390.15 £468.18 Inc. VAT |

|

|

| 1942-002 | 8mm | Oil Pressure Combined with Spring Force | 6.5 | £272.05 £326.46 Inc. VAT |

|

|

| 1942-007 | 15mm | Oil Pressure Combined with Spring Force | 6.5 | £415.37 £498.44 Inc. VAT |

|

|

| 1942-017 | 15mm | Oil Pressure Combined with Spring Force | 9.5 | £494.99 £593.99 Inc. VAT |

|

Threaded Body Work Supports with Metallic Wiper Edge M30 x 1.5 - ROEMHELD B1.9401

- Max. operating pressure 500 bar

- External thread: M30

- Plunger diameter: 16 mm

- Max. flow rate: 25 cm³/s

- Elastic deformation: 4 µm/kN>

- 2 sizes with 3 types of function

Advantages:

- Space-saving threaded-body version

- 2 sizes

- 3 types of function

- Contact force by spring or pneumatically adjustable (1941-0X2)

- Load force 6.5 or 9.5 kN

- Metallic wiper edge and FKM wiper

- Corrosion-resistant interior parts

- Mounting body as accessory

Application:

Hydraulic work supports are used to provide a self-adjusting rest for the workpiece during the machining operations. They compensate the workpiece surface irregularities, also vibration and deflection under machining loads. The threaded-body design allows for spacesaving and direct installation into the fixture body. Oil supply is made through drilled channels.

Description:

In the body of the threaded-body work support a thin-walled locking bush is integrated, which locks cylindrically around the freely-movable support plunger when pressurising the element with hydraulic oil. There are three variations of plunger actuation:

- Spring force

- Air pressure

- Oil pressure combined with spring force The elements are protected against penetration of swarf by a metallic wiper edge and are sealed against liquids.

| Quantity | Unit discount | You Save |

|---|