Roemheld Venting of the Spring Area A0.110

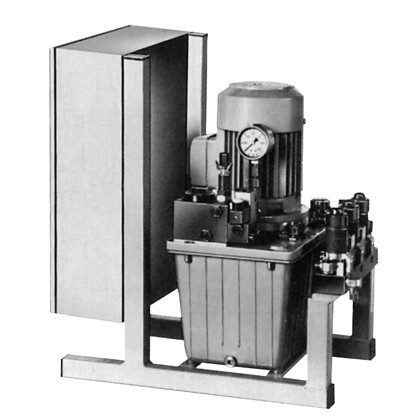

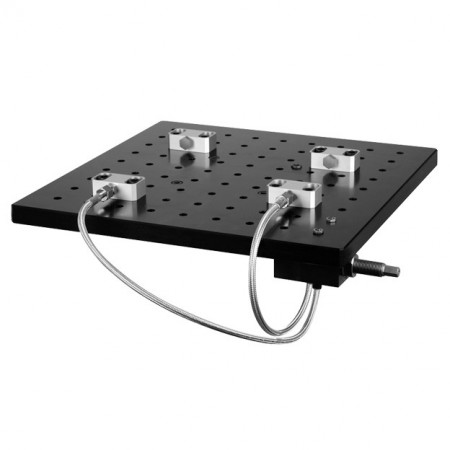

Venting of the spring area, of clamping elements and work supports

Who Is Roemheld?

A family run group with headquarters in Laubach, Germany. Roemheld has over 80 years of experience in hydraulic power workholding. Now operating in over 51 countries and with a portfolio of over 25,000 products and generating an annual turnover of 90 million euros, Roemheld has earned a strong reputation for precision engineering and customer-focused solutions.

Roemheld hydraulic power workholding products are market leading for metal-cutting production engineering solutions. Specialising in clamping elements and systems for production engineering, Roemheld take pride in delivering flexible and cost-effective workholding components and solutions. Designed to increase work throughput while also reducing handling time, raw material required per billet and overall cycle times to reduce manufacturing costs our components and solutions will improve product quality, process precision, and repeatability.

Roemheld products and solutions are used across a wide range of industries; automotive, aerospace, medical, machine tools, special purpose machines, plastics, rubber, food and packaging, white goods, and general engineering. As well as power workholding Roemheld offer their extended QDC, Quick Die Change portfolio, HILMA 5-axis vices, Stark Zero Point clamping systems, M-TECS magnetic clamping solutions, Modulog assembly systems, Kostyrka Clamping Sleeves, and handling equipment. All under the Roemheld brand

HYQUIP & Roemheld

Roemheld take an active role in training designed to support the next generation of production and design engineers. With HYQUIP as your authorised Sales Partner and Distributor, you have unfaltering expert guidance from a partner that has in-depth technical understanding and experience at both a component level and integrated solutions and associated services. All this with the support of Roemheld, a global leader and manufacturer in this production automaton and workholding niche.

Quality

The ISO 9001 registered Roemheld Group feels obliged to offer a continuous process of improvements, reflected within its products. HYQUIP's ISO 9001 certification also guarantees the compliance with standard guidelines.

Environment

Roemheld is certified according to EN ISO 14001, meaning like HYQUIP, they believe protecting the environment is important. Resources such as water, air, energy and raw materials are use as carefully as possible to ensure emissions and waste are kept to a minimum.

|

Die Clamping and Changing Systems from ROEMHELD, everything for a quick, easy and safe die change |

Roemheld Magnetic Clamping Systems

|

Venting of the spring area, of clamping elements and work supports

ROEMHELD L1.101 Linear actuators RA 600 industrial version with limit switch or stroke measuring system

ROEMHELD M8.301 Modulog Clamping Modules workpieces for manual assembly operations.

ROEMHELD M6.201 Floor Modules FMD for use as base frame for height adjustable working places.

ROEMHELD I4.111 Fixture clamp with fixed jaw max. clamping force 15 kN, jaw width 65 mm, double acting

OBSOLETE ITEM - CONTACT HYQUIP

The fixture clamp with fixed jaw consists of a very small basic body with integrated hydraulic cylinder which actuates the movable jaw. All threads and ports are at the bottom to allow a space-saving arrangement of several clamping points in a very limited space.

ROEMHELD H4.300 Concentric Positioning and Clamping Elements: with variable range of clamping, hydraulically operated double acting

Concentric positioning and clamping with two or three-jaw chucks on stationary fixtures is nothing new. In many applications, however, it is not possible to place the relatively large chuck bodies on the fixture. Often the smaller clamping strokes are an additional obstacle. In our development, the individual parts can be connected to a two or multiple-element version.

ROEMHELD G3.800 Contact Bolts in mulitple versions.

ROEMHELD F9.732 Pressure Switch with Hydro-Electric Signal Converter

Hydro-electric pressure switches in piston design convert the pressure in hydraulic systems into electrical signals. The switching point can be continuously adjusted and locked by means of an adjusting knob within different adjusting ranges.

ROEMHELD F9.300 Cutting Ring Unions as per DIN 2353, with Connecting Inserts

ROEMHELD F 9.425 Coupling Units for manual operation, for single and double acting cylinders

This coupling unit is used if the clamping fixture is manually separated from the pressure generator, e.g. in flexible manufacturing systems or when using one pressure generator only for several clamping fixtures. It can be supplied with two different accumulators: Size 1 for clamping fixtures with a big oil volume. Size 2 for clamping fixtures with a small oil volume.

ROEMHELD F 9.290 Rotary Valve Couplings