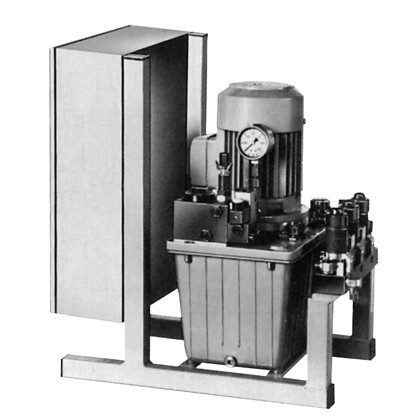

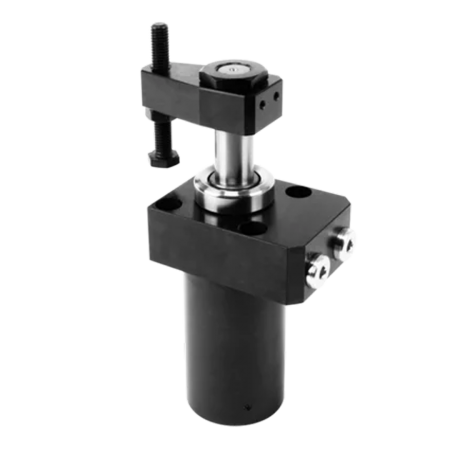

Kostyrka Hydraulic Pressure Generator

Kostyrka hydraulic pressure generators provide high pressure for clamping and supporting

Who Is Roemheld?

A family run group with headquarters in Laubach, Germany. Roemheld has over 80 years of experience in hydraulic power workholding. Now operating in over 51 countries and with a portfolio of over 25,000 products and generating an annual turnover of 90 million euros, Roemheld has earned a strong reputation for precision engineering and customer-focused solutions.

Roemheld hydraulic power workholding products are market leading for metal-cutting production engineering solutions. Specialising in clamping elements and systems for production engineering, Roemheld take pride in delivering flexible and cost-effective workholding components and solutions. Designed to increase work throughput while also reducing handling time, raw material required per billet and overall cycle times to reduce manufacturing costs our components and solutions will improve product quality, process precision, and repeatability.

Roemheld products and solutions are used across a wide range of industries; automotive, aerospace, medical, machine tools, special purpose machines, plastics, rubber, food and packaging, white goods, and general engineering. As well as power workholding Roemheld offer their extended QDC, Quick Die Change portfolio, HILMA 5-axis vices, Stark Zero Point clamping systems, M-TECS magnetic clamping solutions, Modulog assembly systems, Kostyrka Clamping Sleeves, and handling equipment. All under the Roemheld brand

HYQUIP & Roemheld

Roemheld take an active role in training designed to support the next generation of production and design engineers. With HYQUIP as your authorised Sales Partner and Distributor, you have unfaltering expert guidance from a partner that has in-depth technical understanding and experience at both a component level and integrated solutions and associated services. All this with the support of Roemheld, a global leader and manufacturer in this production automaton and workholding niche.

Quality

The ISO 9001 registered Roemheld Group feels obliged to offer a continuous process of improvements, reflected within its products. HYQUIP's ISO 9001 certification also guarantees the compliance with standard guidelines.

Environment

Roemheld is certified according to EN ISO 14001, meaning like HYQUIP, they believe protecting the environment is important. Resources such as water, air, energy and raw materials are use as carefully as possible to ensure emissions and waste are kept to a minimum.

|

Die Clamping and Changing Systems from ROEMHELD, everything for a quick, easy and safe die change |

Roemheld Magnetic Clamping Systems

|

Kostyrka hydraulic pressure generators provide high pressure for clamping and supporting

ROEMHELD M4.501 Lifting Module Twin-strong - manual-hydraulic and electro-hydraulic version

ROEMHELD F 9.440 Multi-couplings - depressurised coupling or coupling against pressure

The multi-coupling is a modification of the threaded coupling elements as per data sheet F 9.430. It comprises of two components, the nipple carrier and the coupling carrier. The advantage of the coupling carrier is the fact that its face is flush in uncoupled condition, thereby it can be easily cleaned by means of the integrated blast air system.

ROEMHELD D8.031 Basic power unit with directional control valve as per customer requirements

ROEMHELD B1.942 Threaded Body Work Support: M 40 x 1.5, with metallic wiper edge, single acting

ROEMHELD B1.853 Swing Clamps with Sturdy Swing Mechanism: Top flange type, with optional position monitoring, double acting

The hydraulic swing clamp is a pull-type cylinder where a part of the total stroke is used to swing the piston. The favourable area ratio (piston/piston rod) allows high clamping forces already at relatively low oil pressures. Due to the sturdy swing mechanism the angle position of the clamping arm remains the same after a slight collision with the workpiece during loading or unloading.

ROEMHELD B1.827 Compact Clamps: Cartridge type, pneumatic position monitoring optional, double acting

The hydraulic compact clamp is a doubleacting pull-type cylinder where a part of the linear stroke is used to swing the clamping lever onto the workpiece. The version with cover is inserted in open bore holes and enables the smallest possible building height. The version without cover requires a closed pocket hole.

ROEMHELD B1.372 Low-Block Clamping Cylinder: single acting with spring return

OBSOLETE ITEM - CONTACT HYQUIP

The preferred application of low-block clamping cylinders are clamping situations where work holding from above is not possible or necessary. The low-clamping effect is caused by the downward motion of the clamping point while the high vertical force guarantees that the workpieces are safely held down.

ROEMHELD B1.552 Double-Acting Block Cylinders with Extended Piston Rods are used if one or several piston positions have to be controlled.

The piston is equipped with a rod of diameter 10 mm that protrudes at the cylinder bottom. At this rod the customer can fix a control cam that is used to operate any limit switch or sensor. As an accessory a complete position monitoring system is available. This unit contains a control cam as well as two inductive proximity switches. The switches can be displaced in the housing which will be screwed to the bottom of the cylinder.

ROEMHELD B1.462 Plunger Piston with integrated pull-back spring, stroke limitation and fastening screw form a unit that cannot be disassembled.

ROEMHELD M8.203 Electrical Operating Elements, Lines and Connectors for the operation of electrical modulog modules, lifting modules and memory function.

ROEMHELD WS 5.3570 - Workholding Systems PC 80 mechanically operated, clamping against the fixed jaw or concentric clamping jaw

Max. Clamping Force: