Wedge Clamps for Tapered Clamping Edge with Form-fit Safety...

- Max. clamping force: 25 .. 630 kN

- Adm. retaining force: 35 .. 820 kN

- Cylinder diameter: 25 .. 125 mm

- Clamping stroke: 20 .. 40 mm

- Max. temperature: 160/100 °C (300 °C on request)

Die clamping and changing systems for press automation, quick changing systems for machines, presses and equipments including Hydraulic, mechanical, electro-mechanical and magnetic clamping elements, die changing technology, roller and ball bars, carrying consoles and changing carts.

HILMA M-TECS 80-B Magnetic Clamping Systems for Sheet Metal Forming

ROEMHELD D8.013 Power units with two-hand operator console

Two-hand operator console is required for fixtures and installations with dangerous applications, in order to keep hands from the effective area of the dangerous movement. Both mushroom push-buttons have to be operated simultaneously within 0.5 seconds. The basic housing of the two-hand operator console is made of plastics and equipped with two mushroom push-buttons and one emergency palm button.

HILMA WZ 8.18344 Roller Bars with Spring Pack for medium loads, for linear movement of dies

HILMA WZ 6.2275 Clamping Nut, Mechanical with blind hole thread, without clamping force display

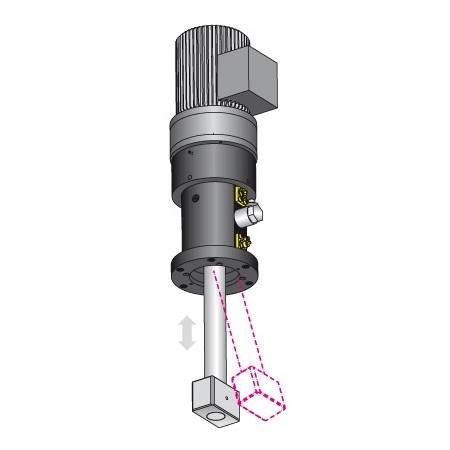

HILMA WZ 5.2650 Swing Clamps electro-mechanical, with position monitoring

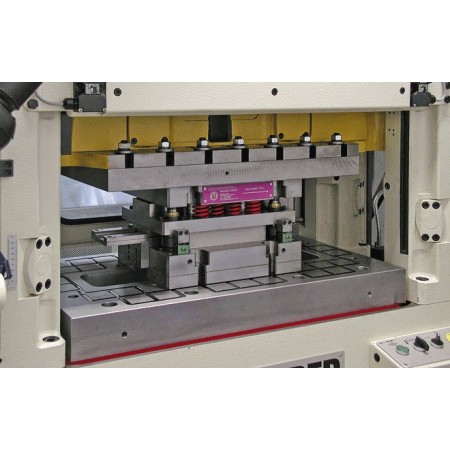

Hilma Automatic Rapid Clamping System suitable for various die sizes

HILMA WZ 2.1833 Swivel and Pull Clamps for presses and high-speed punching presses when the available space is limited

HILMA WZ 3.2204 Sliding Clamps Classic Clamping Block single acting, with spring return max. operating pressure 400 bar, clamping force from 19 to 78 kN

HILMA WZ2.2405 Wedge Clamps for Tapered Clamping Edge double acting, max. clamping force 25 to 630 kN, with locking bolt, without and with position monitoring at the side

HILMA M-TECS 80-F Magnetic Clamping Systems for Mould Carrier Systems

ROEMHELD D8.015 Power units with manual or programmable proportional pressure adjustment

This programmable pressure adjustment allows to adjust the clamping pressure by means of the programme to the corresponding pressure of the machining step; therefore the M-functions of the machines are used. The power unit is particularly suited for applications where pressure adjustments are quite often adjusted manually.